Product Overview

The special innovation full bridge rectification technology combines the multi-stage differentiation of traditional refining methods with traditional distillation, electromagnetic medium heating, polymer bubble decolorization, and falling film separation for distillation treatment of oil products. It is an environmentally friendly, energy-saving, efficient, and safe waste mineral oil refining device.

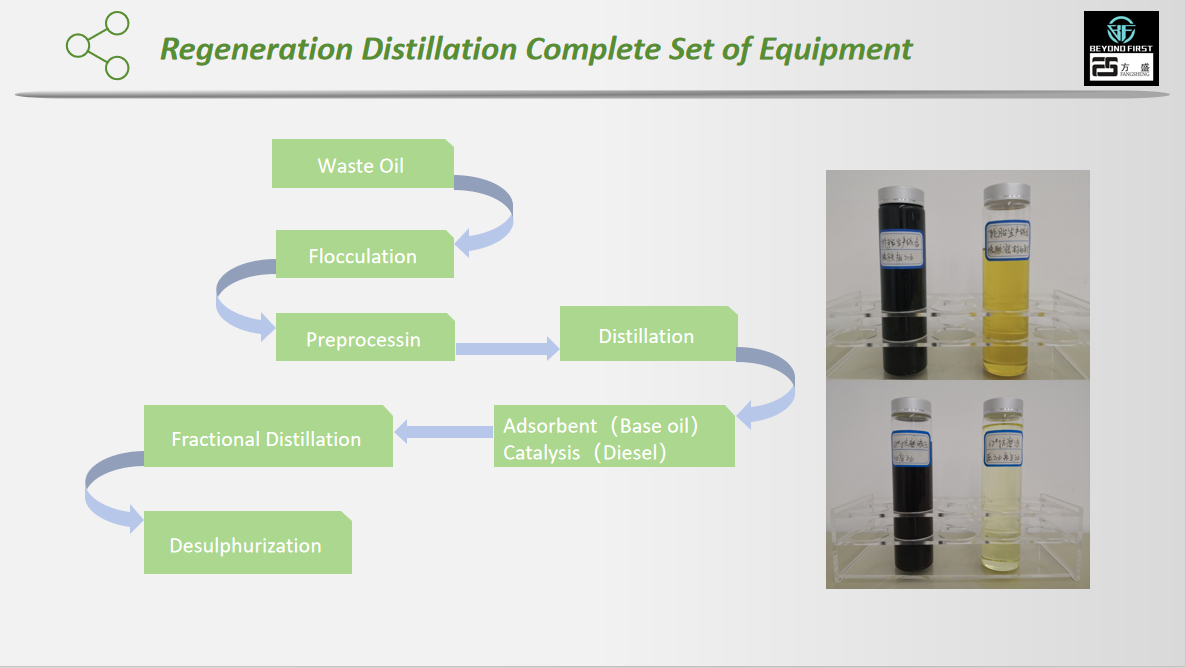

System of Regeneration Distillation Complete Set of Equipment

The process of this Equipment

Twice pretreatment system for waste oil

Thin film evaporation system

reaction system

Adsorption system

Multi stage process fractionation system

Cooling system

Heating system

Vacuum negative pressure pumping system

Exhaust gas treatment system

Integrated utilization system for waste heat recovery

Residue anaerobic solidification system

FAQ

Q:What is the oil yield of this equipment for refining waste oil?

A:The oil yield of the equipment is greatly related to the original feedstock. However, our equipment can achieve an oil yield 20% higher than similar products.

Q:Is the operation of this equipment complicated? Does it require frequent maintenance?

A:The operation of this equipment is simple and convenient, and unlike traditional equipment, it does not require regular shutdowns for maintenance. With proper operation, a check can be done every few months.

Q:Can your company provide a feasibility analysis report for the waste oil refining project?

A:If your company can provide the source of the oil and the processing volume, as well as the required standards for treatment, we can provide a feasibility analysis report for this project for free.

Q:Does the operation of this equipment have additional hazardous waste emissions?

A:No, our leading technology can achieve almost zero emissions.

Q:How long does it take for the complete set of equipment to be delivered and put into use?

A:3 months

Company Profile

Chongqing Fangsheng Purification Equipment Co., Ltd. has been committed to the research and innovation of regeneration and recycling technologies for industrial waste oil and chemical solvents since its establishment in 2007. The recycling rate of products processed by our company's equipment can reach over 99%, with almost zero emissions, providing a good solution for enterprises to reduce costs and increase efficiency, and effectively promoting the development of environmental protection and resource recycling.

Core Technology

- Our independently developed flocculation and flocculation technology removes most of the impurities in the oil and restores the color and quality of the oil

- The independently developed main reaction material can withstand ultra-high temperatures of 1500 degrees Celsius, completely gasifying oil products and carbonizing solid parts

- The independently developed internal structure never gets stuck, saving maintenance time and greatly improving efficiency

- The independently developed catalyst has high efficiency and is renewable and recyclable

Patent Certificate

Since 2007, we have independently developed over a hundred patented technologies

After-Sale Service

- On site installation and debugging of equipment, training of operators

- 24-hour response to customer inquiries and efficient guidance

- Implement regular customer follow-up

- Lifetime provision of technical support