Product Overview

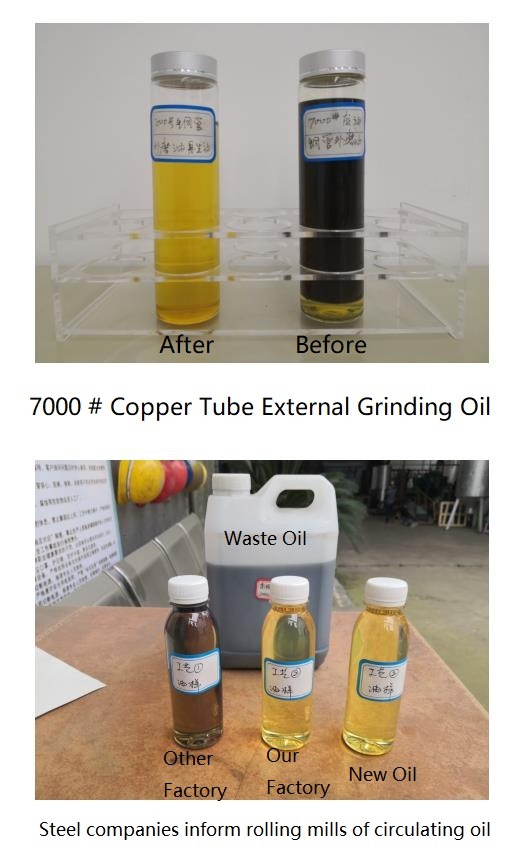

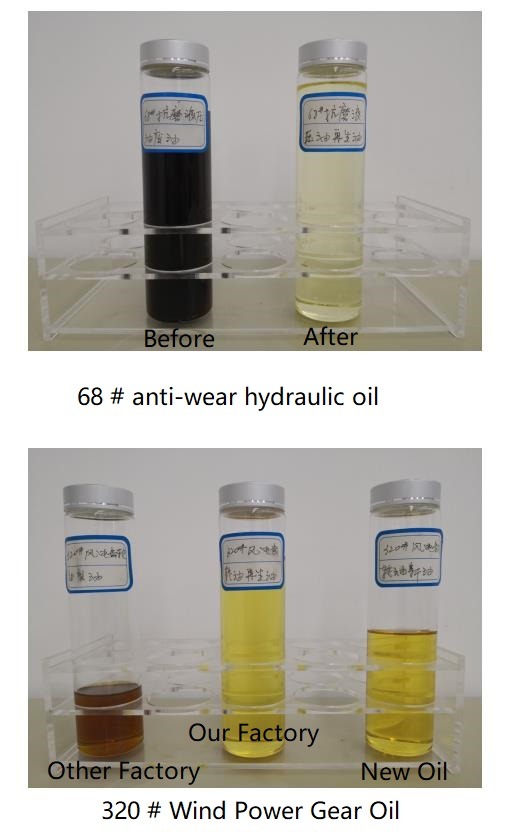

After tens of thousands of experiments, the effective separation of oil and residual carbon, coke, and various metal ion impurities in waste oil has been successfully achieved using physical flocculation method. Various new types of waste oil flocculants can be customized according to the ratio of cold heading oil, forming oil, drawing oil, refining oil, gear oil, hydraulic oil, track oil, and the characteristics of environmental impurities, achieving unlimited reduction of the oil's own usage indicators and realizing circular regeneration.

Company Profile

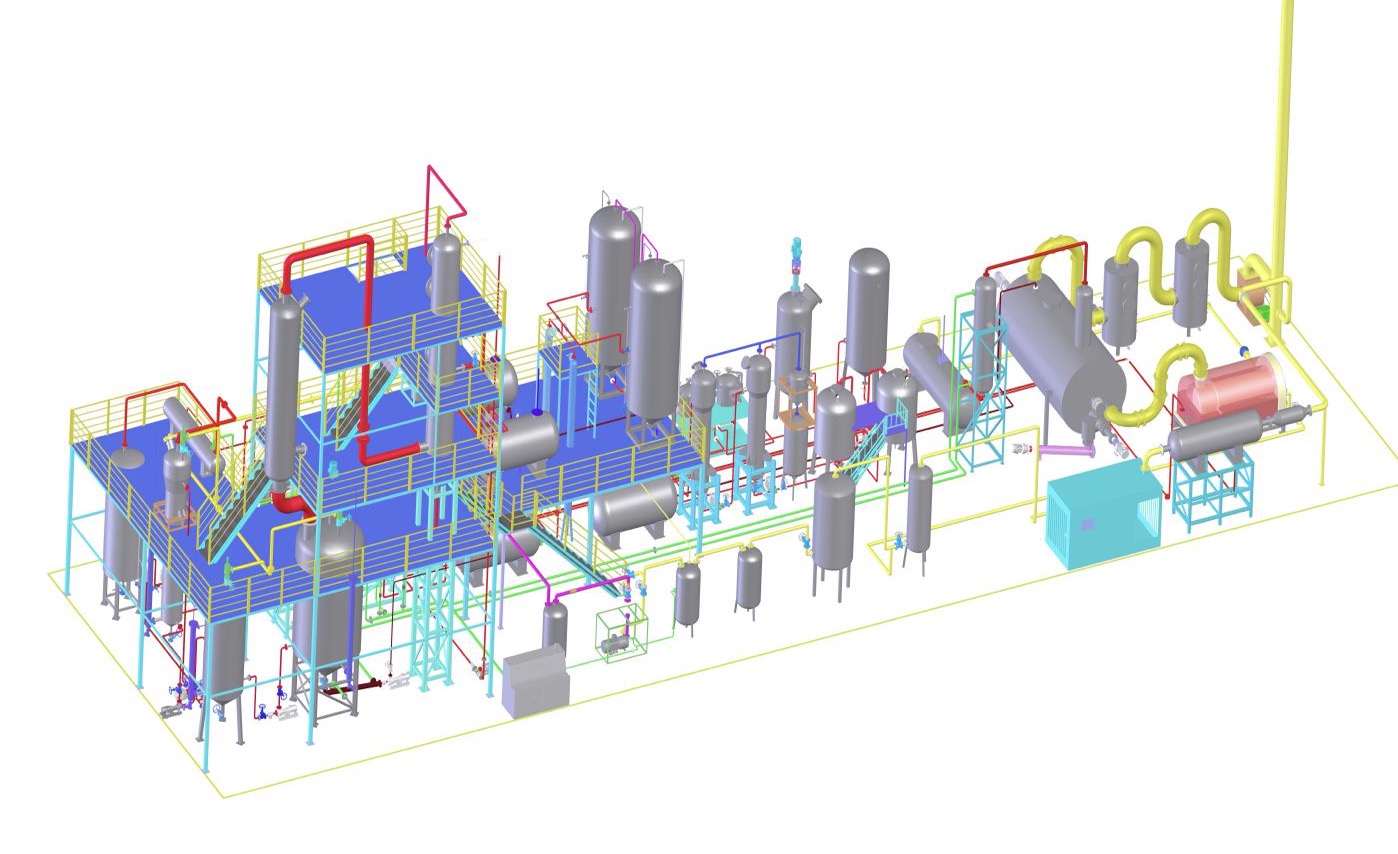

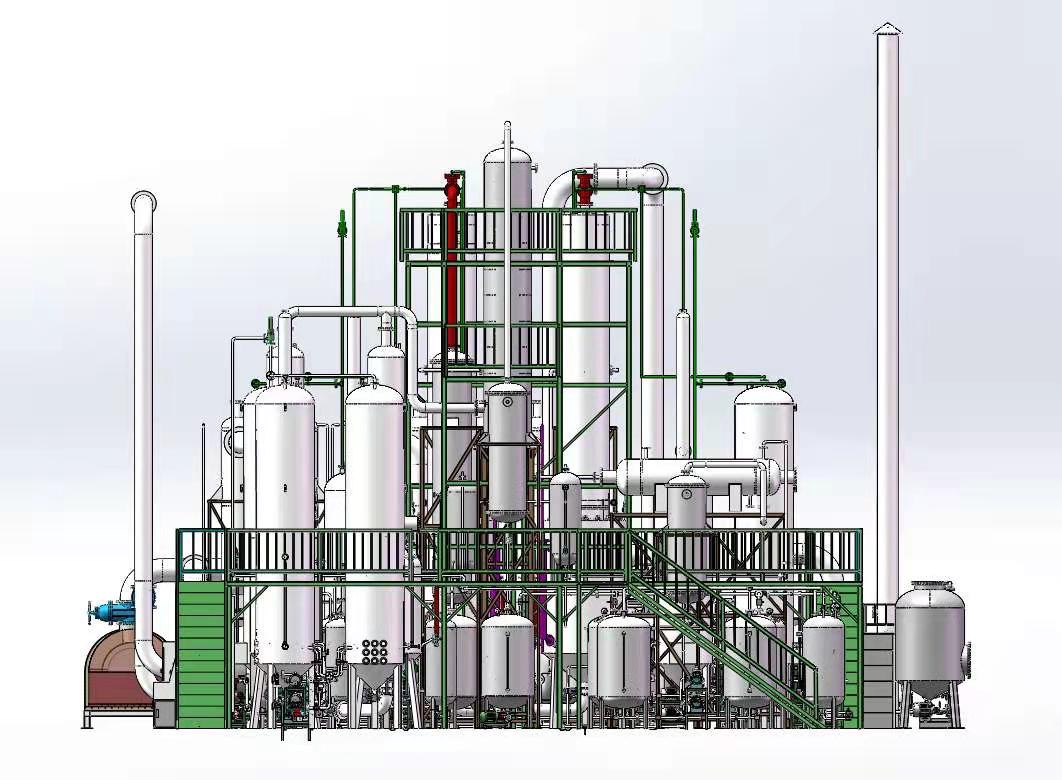

Chongqing Fangsheng Purification Equipment Co., Ltd. has been committed to the research and innovation of regeneration and recycling technologies for industrial waste oil and chemical solvents since its establishment in 2007. The recycling rate of products processed by our company's equipment can reach over 99%, with almost zero emissions, providing a good solution for enterprises to reduce costs and increase efficiency, and effectively promoting the development of environmental protection and resource recycling.

Product Advantages

- 30% more energy-efficient than similar devices

- 20% higher processing and recycling rate than similar devices

- We can design the most suitable hazardous waste treatment plan for you based on your needs

Product Application

- Regeneration and recycling of waste oil from various mechanical equipment

- Refining waste oil from petrochemicals into fuel oil to meet the demand standards of different countries.

- Chemical solvent purification,and reach the emission standards

Patent Certificate

Since 2007, we have independently developed over a hundred patented technologies

After-Sale Service

- On site installation and debugging of equipment, training of operators

- 24-hour response to customer inquiries and efficient guidance

- Implement regular customer follow-up

- Lifetime provision of technical support

FAQ

Q: Is the anti-wear coefficient in lubricating oil affected after the equipment is used for decolorization and filtration?

A: The DTS6 operates at medium to low temperatures and can fully restore the color appearance and kinematic viscosity of the oil without harming its anti-wear coefficient.

Q: Is a filter element required for DTS-6?

A: The DTS-6 utilizes its own proprietary flocculation technology.Flocculants can remove up to 99% of impurities from oil.There is no need for a filter element.

Q: What is the oil output of DTS-6?

A: The oil output ranges from 90% to 99%. The exact amount of oil output depends on the raw material.

Q: Does the equipment heat directly?

A: No, we use the latest technology of electromagnetic eddy current indirect heating, which is more energy-efficient and safer.