Conversion of waste mechanical oil into base oil Distillation equipment Save enterprise costs

Product Introduction

-

High Processing Efficiency

The FS series equipment can efficiently process a variety of industrial waste oils, including waste lubricating oil, gear oil, engine oil, hydraulic oil, as well as oil sludge and oily waste. Its advanced distillation and purification technologies ensure high yields, with oil recovery rates reaching over 98%. -

Energy-Saving and Environmental Protection

The equipment uses electromagnetic induction heating technology, which is more energy-efficient and safer than traditional heating methods. Additionally, the FS series equipment achieves near-zero emissions during operation, meeting environmental requirements. -

Low Maintenance Costs

The main reaction material of the FS series equipment can withstand temperatures up to 1500°C, effectively preventing carbon buildup and reducing maintenance costs. Its design ensures long-term stable operation, minimizing downtime. -

Customized Solutions

The FS series equipment can be customized according to specific customer needs, including processing capacity and operational requirements. This flexibility allows it to meet the needs of different industries and scenarios. -

Advanced Technology

The FS series equipment incorporates multiple innovative technologies, such as anaerobic pyrolysis separation systems and efficient catalysts, ensuring high-quality oil regeneration. These technologies not only increase oil yield but also reduce the generation of hazardous waste. -

Cost-Effective

The equipment is designed to be cost-effective, with regenerable catalysts that further reduce operating costs. This makes the FS series equipment an ideal choice in the field of waste oil treatment. -

Safety and Reliability

The FS series equipment is easy to operate and does not require frequent shutdowns for maintenance. Its advanced technology ensures safe and reliable operation, reducing operational risks.

Conversion of waste mechanical oil into base oil Distillation equipment,Distillation equipment Save enterprise costs,Conversion of waste mechanical oil into base oil Distillation equipment Save enterprise costs

Comparison diagram of waste oil regeneration

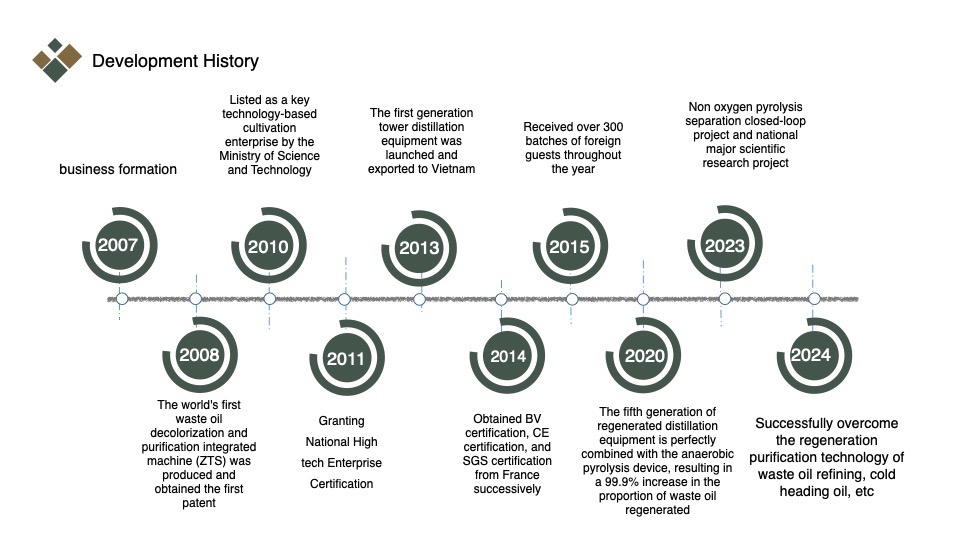

Company Introduction

Patent Introduction

Customer photo

Our company has an extensive customer base and has collaborated with numerous enterprises across various industries.

FAQ

Q:What is the oil yield of this equipment for refining waste oil?

A:The oil yield of the equipment is greatly related to the original feedstock. However, our equipment can achieve an oil yield 20% higher than similar products.

Q:Is the operation of this equipment complicated? Does it require frequent maintenance?

A:The operation of this equipment is simple and convenient, and unlike traditional equipment, it does not require regular shutdowns for maintenance. With proper operation, a check can be done every few months.

Q:Can your company provide a feasibility analysis report for the waste oil refining project?

A:If your company can provide the source of the oil and the processing volume, as well as the required standards for treatment, we can provide a feasibility analysis report for this project for free.

Q:Does the operation of this equipment have additional hazardous waste emissions?

A:No, our leading technology can achieve almost zero emissions.

Q: What kind of waste oil can this equipment process?

A: This equipment can handle any condition of industrial waste oil or oil sludge, including lubricating oil, gear oil, engine oil, hydraulic oil, and mixtures thereof.

Q:How long does it take for the complete set of equipment to be delivered and put into use?

A:3 months

contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp :at+85292340729.

Conversion of waste mechanical oil into base oil Distillation equipment Save enterprise costs

Product Introduction

-

Advanced Distillation Technology: Capable of processing various types of waste oils, including lubricating oil, gear oil, engine oil, hydraulic oil, and more.

-

Energy-Efficient and Environmentally Friendly: Utilizes advanced heating technology to minimize energy consumption and achieve near-zero emissions during operation.

-

High Yield: Optimized distillation processes result in oil recovery rates of over 98%.

-

Low Maintenance Costs: The equipment is designed to reduce carbon buildup and blockages, lowering maintenance frequency.

-

Customized Solutions: Can be tailored to meet specific customer needs, catering to different industries and application scenarios.

Conversion of waste mechanical oil into base oil Distillation equipment,Distillation equipment Save enterprise costs,Conversion of waste mechanical oil into base oil Distillation equipment Save enterprise costs

Comparison diagram of waste oil regeneration

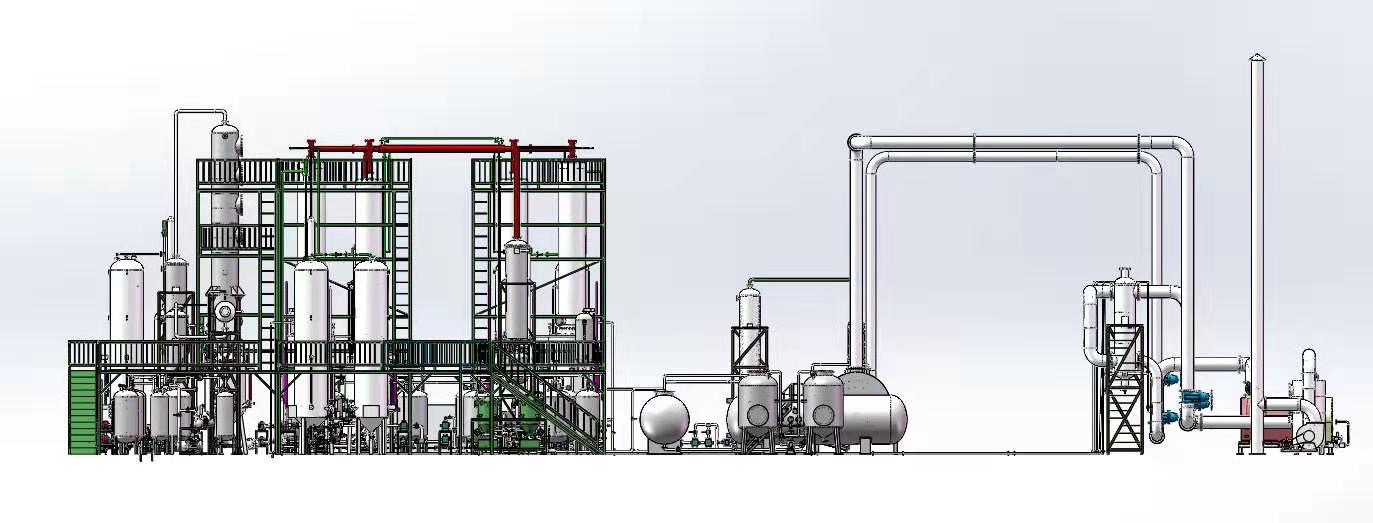

Company Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. is a high-tech enterprise specializing in the research and development of regeneration and purification technologies for industrial waste oil and waste liquids. With technological innovation at its core, the company holds over 100 patents and offers efficient and environmentally friendly regeneration solutions to customers worldwide. Its core products, such as the DTS Multifunctional Low-Temperature Purification All-in-One Machine and the FS-HDM5 Complete Distillation Equipment, are widely used in industries like petroleum, chemical, mechanical manufacturing, shipping, and power. These products help enterprises achieve resource recycling and sustainable development. The company is committed to advancing the fields of environmental protection and resource recycling through its advanced technologies and high-quality services.

Conversion of waste mechanical oil into base oil Distillation equipment,Distillation equipment Save enterprise costs,Conversion of waste mechanical oil into base oil Distillation equipment Save enterprise costs

Patent Introduction

Customer photo

FAQ

Q:What is the oil yield of this equipment for refining waste oil?

A:The oil yield of the equipment is greatly related to the original feedstock. However, our equipment can achieve an oil yield 20% higher than similar products.

Q:Is the operation of this equipment complicated? Does it require frequent maintenance?

A:The operation of this equipment is simple and convenient, and unlike traditional equipment, it does not require regular shutdowns for maintenance. With proper operation, a check can be done every few months.

Q:Can your company provide a feasibility analysis report for the waste oil refining project?

A:If your company can provide the source of the oil and the processing volume, as well as the required standards for treatment, we can provide a feasibility analysis report for this project for free.

Q:Does the operation of this equipment have additional hazardous waste emissions?

A:No, our leading technology can achieve almost zero emissions.

Q: What kind of waste oil can this equipment process?

A: This equipment can handle any condition of industrial waste oil or oil sludge, including lubricating oil, gear oil, engine oil, hydraulic oil, and mixtures thereof.

Q:How long does it take for the complete set of equipment to be delivered and put into use?

A:3 months

contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp :at+85292340729.