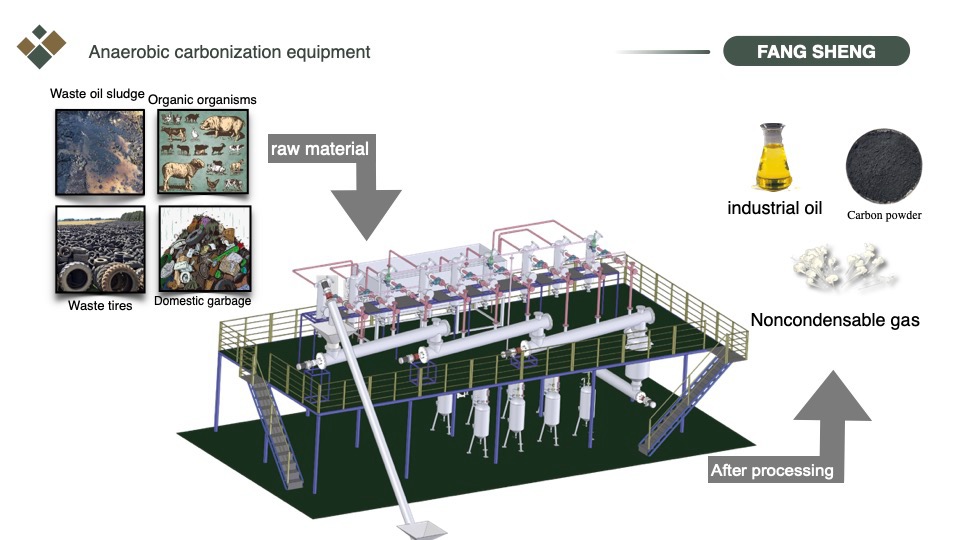

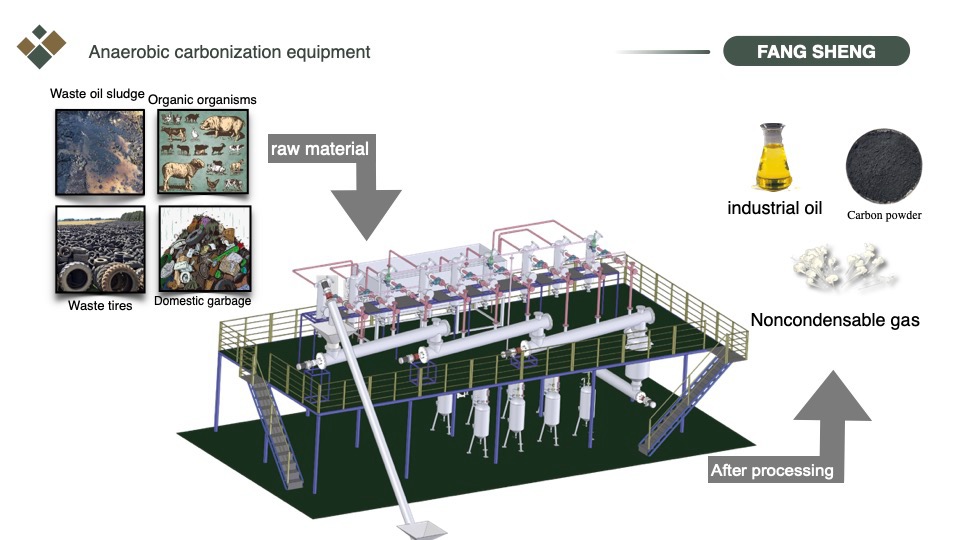

Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment Extract more industrial oil

Product Introduction

The anaerobic carbonization equipment thermally decomposes organic waste in a high-temperature, oxygen-free environment, transforming it into high-value products such as combustible gases (methane, hydrogen, etc.), tar, and solid carbon. This technology not only reduces and harmlessly treats waste but also creates economic value through resource recovery.

1. Efficient Pyrolysis Technology

The equipment employs anaerobic carbonization technology, breaking down waste into combustible gases, tar, and solid carbon through precise temperature control and optimized reaction conditions. This process reduces the volume of waste while maximizing the recovery of valuable resources.

2.Environmental Protection and Harmlessness

The equipment does not produce harmful substances such as dioxins and furans during operation, fundamentally solving the environmental pollution issues associated with traditional methods. The exhaust gas treatment system uses advanced purification technologies to ensure emissions meet strict environmental standards.

3. Resource Recovery and Reuse

The equipment converts waste into high-value products like combustible gases, bio-oil, and solid carbon, which can be further utilized as energy sources or chemical raw materials. This achieves the maximum resource utilization and economic value of waste.

4. Robust and Automated Operation

Made from high-temperature and corrosion-resistant materials, the equipment ensures long-term stable operation. It is equipped with an intelligent PLC control system for automated operation, reducing labor costs.

5. Continuous Production and High Efficiency

The equipment supports continuous production, capable of efficiently processing large volumes of waste with a daily capacity of up to 120 tons. This continuous operation mode not only improves processing efficiency but also reduces downtime.

Applicable scenarios

-

Organic Waste Treatment: Reducing, harmlessly treating, and recycling waste oil, waste oil sludge, waste tires, sludge, and high-concentration organic wastewater.

-

Agricultural and Forestry Waste Treatment: Converting straw, rice husks, etc., into biochar for soil improvement or energy use.

-

Municipal Solid Waste Treatment: Transforming waste into reusable resources through low-temperature anaerobic pyrolysis, reducing secondary pollution.

-

Resource Recovery and Reuse: Converting waste into high-value products such as combustible gases, bio-oil, and solid carbon.

Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment,High temperature anaerobic carbonization equipment Extract more industrial oil,Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment Extract more industrial oil

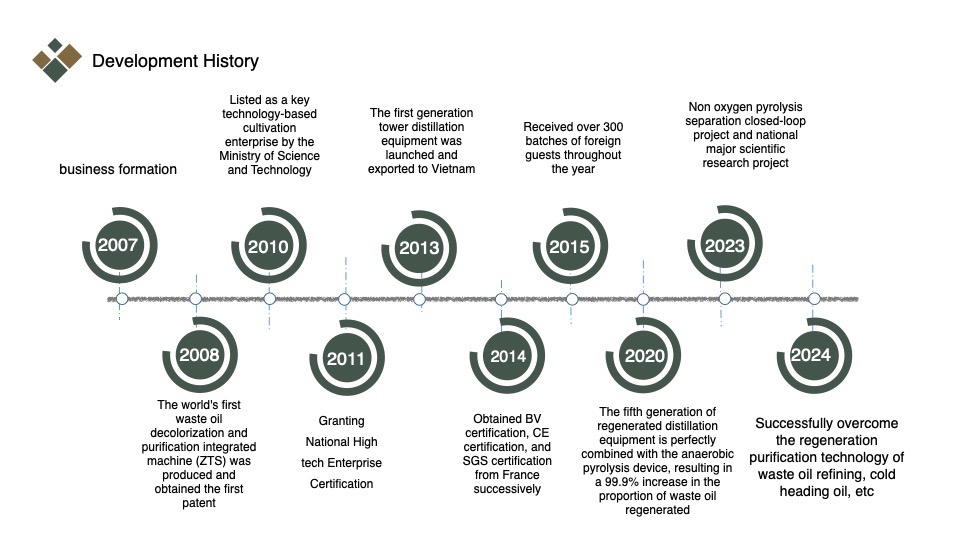

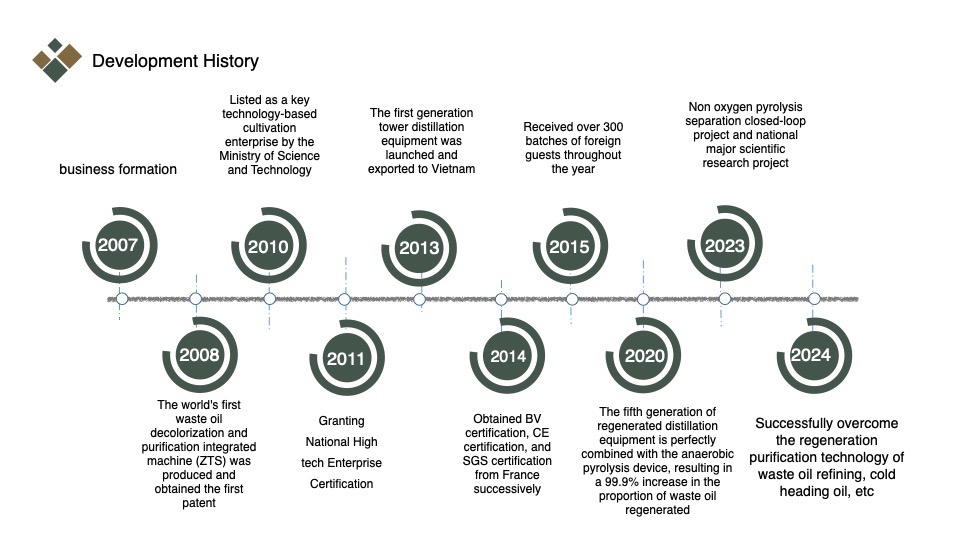

Company Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. was established in 2007 and is a high-tech enterprise specializing in the treatment of organic waste. The company is committed to providing efficient and environmentally friendly solutions for the treatment of waste oil, waste oil sludge, waste tires, sludge, and other types of waste through anaerobic carbonization technology. With over 100 patents, Fangsheng is at the forefront of technological innovation and product development in its industry. Our products are widely used in both domestic and international markets and have won the trust of numerous customers. We are dedicated to promoting environmental protection and sustainable development by transforming waste into valuable resources and creating economic and environmental benefits for our customers.

Patent Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. holds over 100 patents, covering multiple fields including the treatment of waste oil, waste oil sludge, and waste tires. These patents reflect the company's robust capabilities in technological innovation and product development.

Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment,High temperature anaerobic carbonization equipment Extract more industrial oil,Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment Extract more industrial oil

Customer photo

Chongqing Fangsheng Purification Equipment Co., Ltd. has won the trust of numerous domestic and international customers with its outstanding technology and reliable equipment. Our extensive customer base, spanning multiple countries and regions, fully demonstrates Fangsheng's global market influence and brand value.

Q&A

Q: What hazardous waste can this device handle?

A: Household waste, waste tires, animal carcasses, oily sludge.

Q: What additional value can be generated by using this device?

A: In addition to processing a large amount of hazardous waste, it can also produce carbon and a small amount of base oil .

Q: What is the working principle and process of this device?

A: Gasify and carbonize solids at high temperatures, and then discharge them.

Q: Will the emissions from the equipment still cause damage to the environment?

A: After processing, non condensable steam and carbon are discharged, achieving zero emissions of pollutants completely.

Q: What are the specifications and volume of this device

A: As this device is a customized product, we need to first understand the customer's production requirements before providing specific parameters.

contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp :at+85292340729.

Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment Extract more industrial oil

Product Introduction

-

Efficient Anaerobic Pyrolysis Technology

The equipment can heat solid organic waste in an oxygen-free environment. By exploiting the thermal instability of organic materials, it breaks the carbon and hydrogen bonds in large molecules to generate small-molecule combustible gases (such as methane, ethane, propane, butane, CO, and hydrogen), condensable oils, and solid carbon. -

No Adhesion, No Coking, No Blockage

The SF-HDM6 employs an innovative high-temperature and corrosion-resistant chain grate pyrolysis furnace, completely solving the common problems of coking, blockage, and material adhesion found in traditional equipment, ensuring long-term stable operation. -

Robust and Durable with Long Service Life

The equipment features an enhanced anti-coking nano-ceramic coating, segmented control to regulate material conditions, and rolling scrapers to prevent contamination and blockage. Main components are made of alloy steel and other corrosion-resistant materials, with heat exchangers using highly corrosion-resistant materials, ensuring a service life of over 10 years. -

Continuous Operation and Efficient Feeding

The anaerobic pyrolysis carbonization technology achieves high-efficiency continuous feeding, breaking through the limitations of traditional intermittent feeding. Waste shredding, feeding, and slag discharge are all automated, ensuring the continuity and stability of the treatment process. -

Precise Temperature Control and Safe Operation

The equipment uses an innovative anaerobic pyrolysis molten salt heating system, which provides uniform and efficient heating with a working temperature of around 1500°C. The molten salt system has high specific heat capacity, high heat transfer capability, and low viscosity, ensuring safe operation under atmospheric pressure. -

Environmental Protection and Zero Emissions

The SF-HDM6 equipment does not produce harmful substances such as dioxins and furans during operation, fundamentally solving the pollution problems associated with traditional treatment methods.

Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment,High temperature anaerobic carbonization equipment Extract more industrial oil,Equipment for extracting base oil from rubber products High temperature anaerobic carbonization equipment Extract more industrial oil

Applicable scenarios

-

Treatment of Solid Organic Waste: Including oil sludge, rubber products, and municipal solid waste.

-

Resource Recovery: By using anaerobic pyrolysis technology, it achieves oil recovery and solid carbonization, reducing the generation of hazardous waste.

Company Introduction

Patent Introduction

Customer photo

FAQ

Q: What hazardous waste can this device handle?

A: Household waste, waste tires, animal carcasses, oily sludge.

Q: What additional value can be generated by using this device?

A: In addition to processing a large amount of hazardous waste, it can also produce carbon and a small amount of base oil .

Q: What is the working principle and process of this device?

A: Gasify and carbonize solids at high temperatures, and then discharge them.

Q: Will the emissions from the equipment still cause damage to the environment?

A: After processing, non condensable steam and carbon are discharged, achieving zero emissions of pollutants completely.

Q: What are the specifications and volume of this device

A: As this device is a customized product, we need to first understand the customer's production requirements before providing specific parameters.

contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp :at+85292340729.