Equipment for extracting lubricating oil from household waste Extract more industrial oil

Product Introduction

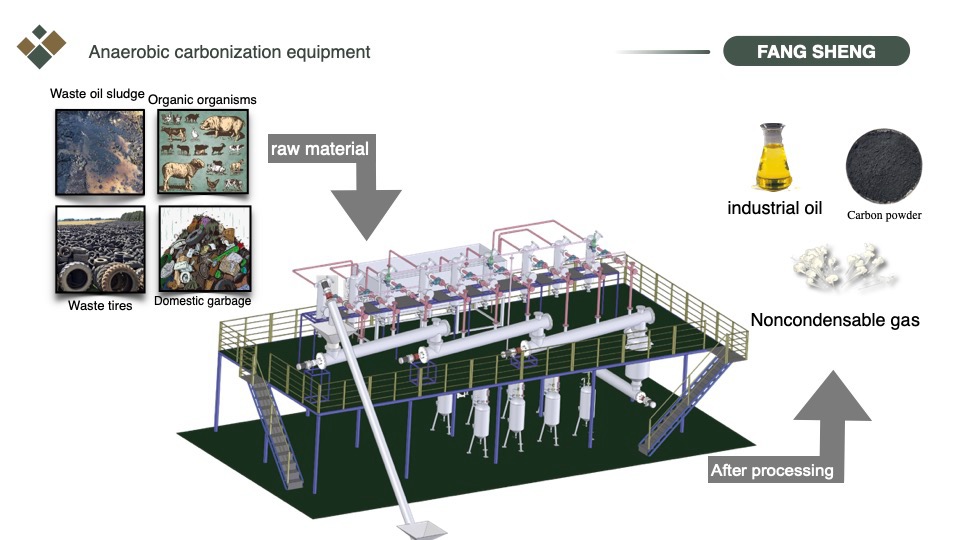

Chongqing Fangsheng Purification Equipment Co., Ltd.'s anaerobic carbonization equipment is an advanced organic waste treatment system, widely used for the processing of waste oil, waste oil sludge, waste tires, sludge, and high-concentration organic wastewater. This equipment transforms waste materials into high-value products such as combustible gases (methane, hydrogen, etc.), tar, and solid carbon through high-temperature pyrolysis in an oxygen-free environment, achieving waste reduction, harmlessness, and resource utilization.

1. Efficient Pyrolysis Technology

The equipment employs anaerobic carbonization technology, breaking down waste into combustible gases, tar, and solid carbon through precise temperature control and optimized reaction conditions. This process reduces the volume of waste while maximizing the recovery of valuable resources.

2. Environmental Protection and Harmlessness

During operation, the equipment does not produce harmful substances such as dioxins and furans, fundamentally solving the environmental pollution issues associated with traditional treatment methods. The exhaust gas treatment system uses advanced purification technologies to ensure emissions meet strict environmental standards.

3. Resource Recovery and Reuse

The anaerobic carbonization equipment converts waste into high-value products such as combustible gases, bio-oil, and solid carbon. These products can be further utilized as energy sources or chemical raw materials, maximizing the resource utilization and economic value of waste.

4. Robust and Automated Operation

Made from high-temperature and corrosion-resistant materials, the equipment ensures long-term stable operation. It is equipped with an intelligent PLC control system for automated operation, reducing labor costs.

5. Continuous Production and High Efficiency

The equipment supports continuous production, capable of efficiently processing large volumes of waste with a daily capacity of up to 120 tons. This continuous production mode not only improves processing efficiency but also reduces downtime.

Equipment for extracting lubricating oil from household waste Extract more industrial oil

Applicable scenarios

Anaerobic carbonization technology is widely used in various waste treatment scenarios, especially for the processing of organic wastes such as waste oil, waste oil sludge, waste tires, sludge, and high-concentration organic wastewater. Through high-temperature pyrolysis in an oxygen-free environment, these wastes are converted into combustible gases (such as methane and hydrogen), tar, and solid carbon, achieving waste reduction, harmlessness, and resource utilization.

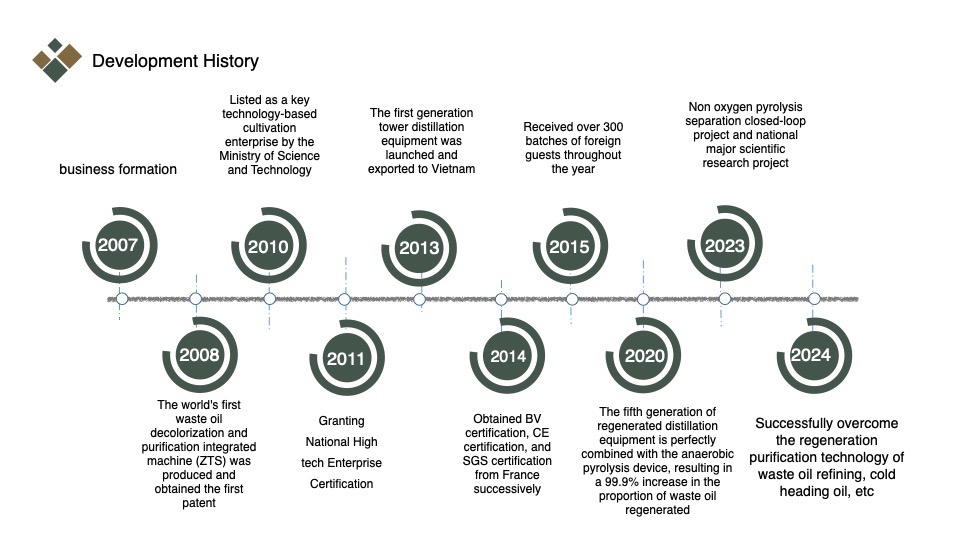

Company Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. places great emphasis on technological innovation and holds over 100 patents, covering areas such as waste oil treatment, waste liquid purification, and anaerobic carbonization. Our patented technologies include the “Waste Oil Flocculation and Filtration Regeneration Device,” “High-Temperature Magnetic Level Display Device for Liquids,” and “Decolorization and Purification Integrated Machine.” These innovations not only significantly enhance the efficiency and quality of waste oil and liquid treatment but also drive technological progress in the industry. With these pioneering patents, the company has received multiple national awards for high-tech innovation and invention and has been recognized as a national high-tech enterprise, fully demonstrating our strength in technological research and development as well as intellectual property protection.

Patent Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. places great emphasis on technological innovation and holds over 100 patents, covering areas such as waste oil treatment, waste liquid purification, and anaerobic carbonization. Our patented technologies include the “Waste Oil Flocculation and Filtration Regeneration Device,” “High-Temperature Magnetic Level Display Device for Liquids,” and “Decolorization and Purification Integrated Machine.” These innovations not only significantly enhance the efficiency and quality of waste oil and liquid treatment but also drive technological progress in the industry. With these pioneering patents, the company has received multiple national awards for high-tech innovation and invention and has been recognized as a national high-tech enterprise, fully demonstrating our strength in technological research and development as well as intellectual property protection.

Customer photo

Chongqing Fangsheng Purification Equipment Co., Ltd. has garnered extensive market recognition and amassed a substantial customer base both domestically and internationally. Our clients span across numerous industries, ranging from large domestic enterprises to international partners, all of whom have highly praised our anaerobic carbonization equipment. This broad customer foundation not only reflects our influence within the industry but also highlights the global competitiveness of our products.

Equipment for extracting lubricating oil from household waste Extract more industrial oil

Q&A

Q: What hazardous waste can this device handle?

A: Household waste, waste tires, animal carcasses, oily sludge.

Q: What additional value can be generated by using this device?

A: In addition to processing a large amount of hazardous waste, it can also produce carbon and a small amount of base oil .

Q: What is the working principle and process of this device?

A: Gasify and carbonize solids at high temperatures, and then discharge them.

Q: Will the emissions from the equipment still cause damage to the environment?

A: After processing, non condensable steam and carbon are discharged, achieving zero emissions of pollutants completely.

Q: What are the specifications and volume of this device

A: As this device is a customized product, we need to first understand the customer's production requirements before providing specific parameters.

contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp :at+85292340729.