The DTS Multifunctional Low-Temperature Purification All-in-One Machine is one of the flagship products of Chongqing Fangsheng Purification Equipment Co., Ltd., specifically designed for the efficient regeneration and purification of industrial waste oil. This advanced equipment utilizes low-temperature purification technology, operating below 100 degrees Celsius to protect the original properties of the oil and prevent degradation caused by high-temperature processing. The DTS machine employs a unique magnetic filtration technology without traditional filter elements, achieving highly efficient separation of impurities while reducing operational costs and maintenance workload. The purified oil meets new oil standards with a recovery rate of over 99%, and nearly zero emissions.

In addition, the DTS machine features automated operation with intelligent control systems, enabling unattended operation and further improving work efficiency. With its high efficiency, energy-saving, and environmentally friendly characteristics, the DTS Multifunctional Low-Temperature Purification All-in-One Machine has become the preferred solution for waste oil treatment for many enterprises worldwide. It is widely used in industries such as petroleum, chemical, mechanical manufacturing, shipping, and power, helping companies achieve cost reduction, efficiency enhancement, and sustainable development goals.

oil filter Industrial waste oil recycling machinery,Industrial waste oil recycling machinery Non centrifugal machine,oil filter Industrial waste oil recycling machinery Non centrifugal machine

Comparison diagram of waste oil regeneration

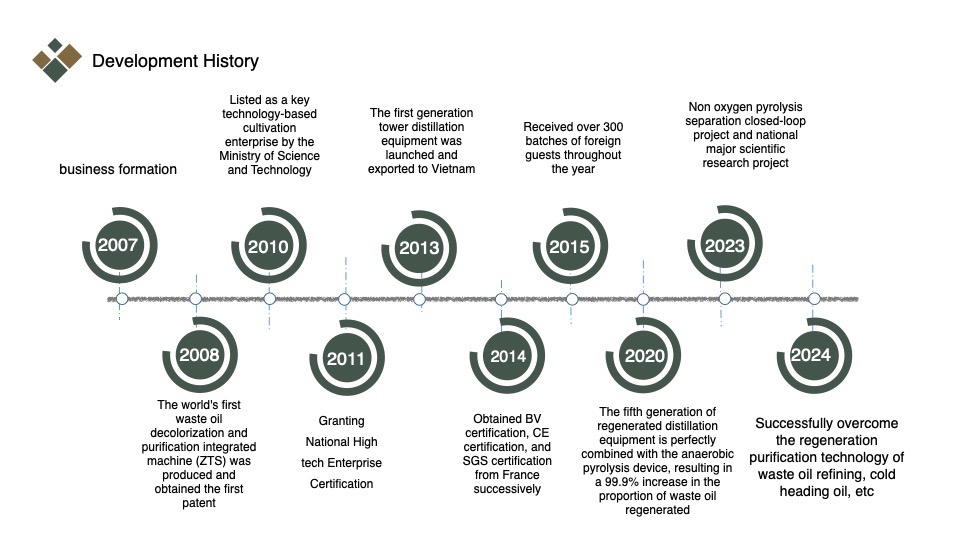

Company Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. is a high-tech enterprise specializing in the research and development of regeneration and purification technologies for industrial waste oil and waste liquids. Since its establishment in 2007, the company has leveraged its expertise in distillation, fractionation, filtration, and separation technologies to provide comprehensive solutions for the purification and regeneration of industrial waste oil and waste liquids. With hundreds of innovative patents, Fangsheng is a national high-tech enterprise whose core team has over 20 years of experience in waste oil and liquid treatment.

The company's flagship products, including the FS-HDM waste oil distillation equipment, FS-MDP semi-automatic waste oil regeneration distillation equipment, ZTS decolorization and oil purification machine, and DTS multifunctional purification and decolorization unit, are widely used in industries such as petroleum, chemical, mechanical, shipping, and power. Known for their efficiency, environmental friendliness, and energy-saving capabilities, these products have earned the trust of numerous enterprises both domestically and internationally.

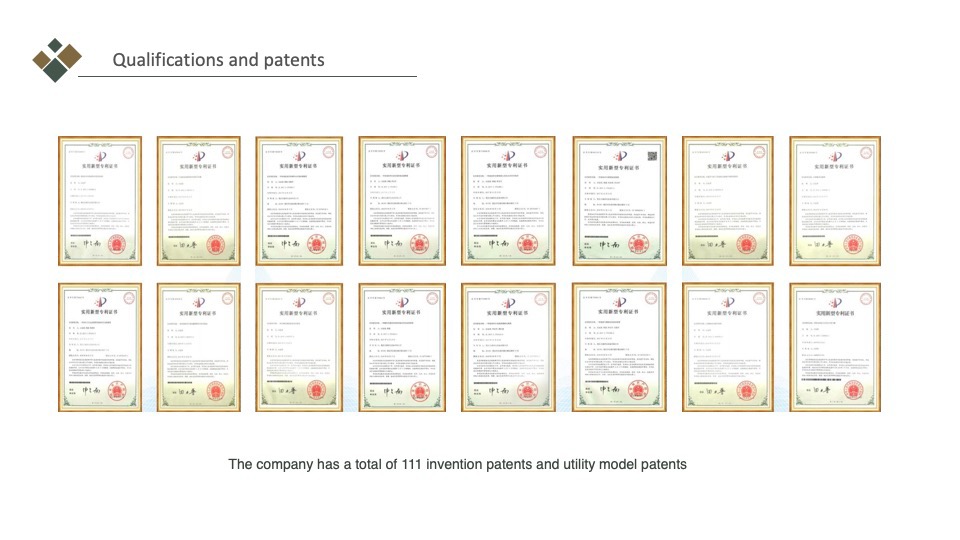

Patent Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. places great emphasis on technological innovation and intellectual property protection. Since its establishment in 2007, the company has accumulated over 100 patents. These patents cover multiple core technologies in the field of industrial waste oil treatment and chemical solvent recycling, including filter-free purification systems, efficient separation techniques, and energy-saving processes. Through continuous R&D investment and strategic patent layout, the company has not only provided a solid technical foundation for its products but also significantly enhanced its market competitiveness, establishing a leading position in technology on a global scale.

oil filter Industrial waste oil recycling machinery,Industrial waste oil recycling machinery Non centrifugal machine,oil filter Industrial waste oil recycling machinery Non centrifugal machine

Customer photo

Chongqing Fangsheng Purification Equipment Co., Ltd. boasts a global customer network. With its outstanding technological capabilities and high-quality products and services, the company has earned the trust and recognition of enterprises in many countries and regions worldwide. From Europe to the Americas, and from Asia to Oceania, our customers span a wide range of industries, including petroleum, chemical, mechanical manufacturing, shipping, power, and automotive. Whether large multinational corporations or small-to-medium-sized local factories, our solutions provide them with efficient, environmentally friendly, and sustainable options for waste oil treatment and resource recycling. We are committed to offering customized solutions tailored to each customer's unique needs, helping them achieve green production and sustainable development in the global market.

FQA

Q: Will the anti-wear factor in the lubricant be damaged or lost after being decolorized and filtered by the equipment?

A: As DTS6 operates at medium to low temperatures, it can completely restore its appearance and kinematic viscosity without damaging its anti-wear factor.

Q: What is the replacement cycle for the filter element of DTS-6

A: DTS-6 adopts the latest technology. No need to replace the filter element, just clean it regularly.

Q: What is the oil yield of DTS-6?

A: 90% -99%. The specific oil yield should be determined based on the raw materials.

Q: What is the degree of reduction of waste oil that can be achieved?

A: Due to our globally leading products, we are able to reduce oil products to 99.9% using the latest technology.

Q:What types of oil can DTS handle

A: DTS can process used single type waste oil (including lubricating oil/gear oil/chain oil/hydraulic oil, etc.)

Q:Can DTS handle waste oil mixed with multiple varieties

A:Can handle waste oil other than high-temperature engine oil

Contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp at:+85292340729.