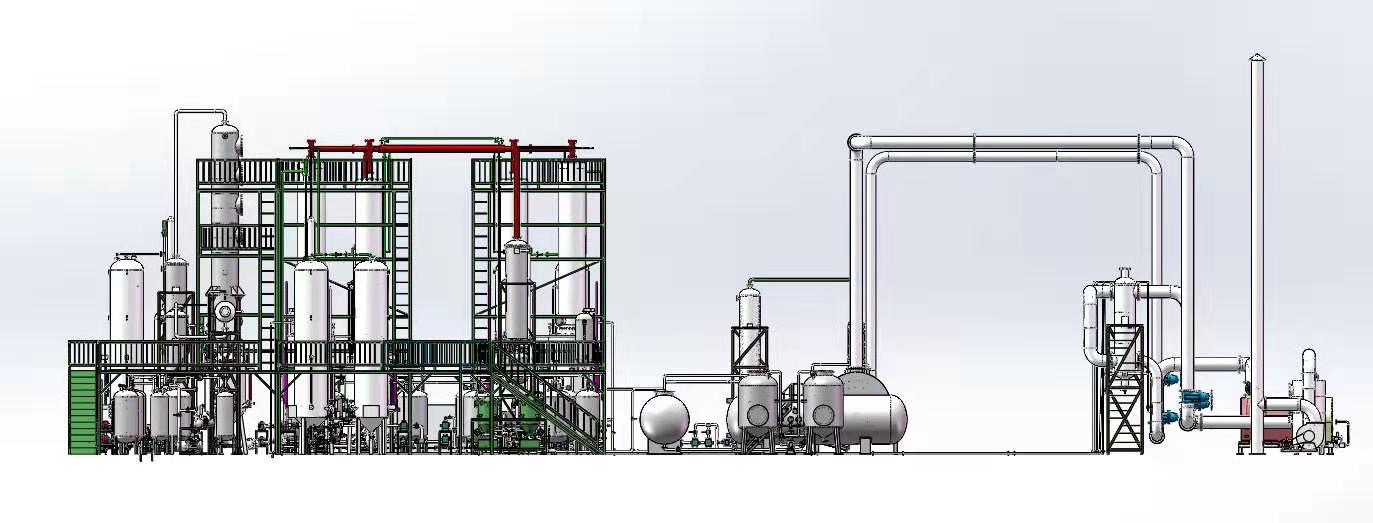

Used Oil Refinery Waste chain oil recycling machinery Oil output of over 95%

Product Introduction:

It is an upgraded version of the DTS multifunctional decolorization and purification all-in-one machine. It can achieve waste oil purification at temperatures below 100 degrees without damaging the oil film and ensuring the highest oil quality.

This machine can effectively restore a single waste oil (including lubricating oil/anti-wear hydraulic oil/engine oil/gear oil/chain oil), making the waste oil index reach the standard of new oil, and put it into use in the original equipment without causing any damage to the original equipment.

Due to the use of the latest flocculation technology, this machine does not have a filter element! No filter element! No filter element!

Without a filter element, there are no consumables that need to be replaced frequently, saving processing costs and the cost of manual replacement or cleaning of the filter element.

|

|

|

Used Oil Refinery Waste chain oil recycling machinery,Waste chain oil recycling machinery Oil output of over 95%,Used Oil Refinery Waste chain oil recycling machinery Oil output of over 95%

|

|

|

|

Resource Reuse By recycling waste oil, a large amount of new raw materials can be saved and energy consumption can be reduced. |

Reduce environmental pollution If waste oil is not properly treated and disposed of, it can cause serious environmental pollution. |

economic performance Process a single variety of waste oil into new oil indicators, use them in the original equipment, reduce production costs, and lower the cost of purchasing new oil products |

Processing technology and cost

Waste oil contains various pollutants that require advanced treatment processes and equipment, increasing the difficulty and cost of treatment.

Quality and stability

It is difficult to completely remove impurities and pollutants from waste oil during the recycling process, resulting in unstable quality and performance of the regenerated products.

Potential health and safety risks

The pollutants and harmful substances in waste oil pose potential risks to human health.

Product Features:

- The independently developed flocculant can dehydrate, desulfurize, and degumm, making the treatment of waste oil more thorough.

- Leading the industry in using electromagnetic eddy current technology for indirect heating, without damaging the oil film, while saving 30% of energy consumption.

- Independently developed reactor internal structure, fully automatic operation, never coking, efficiency increased by 250%.

- It can achieve waste oil purification at temperatures below 100 degrees without damaging the oil film and ensuring the highest oil quality.

- The processed oil can be used in the original equipment without causing any damage to the original equipment.

- Professional technical team, capable of OEM or ODM according to customer needs, and able to provide overall solutions.

Comparison diagram of waste oil regeneration:

On the left is the waste oil processed by our company's machines

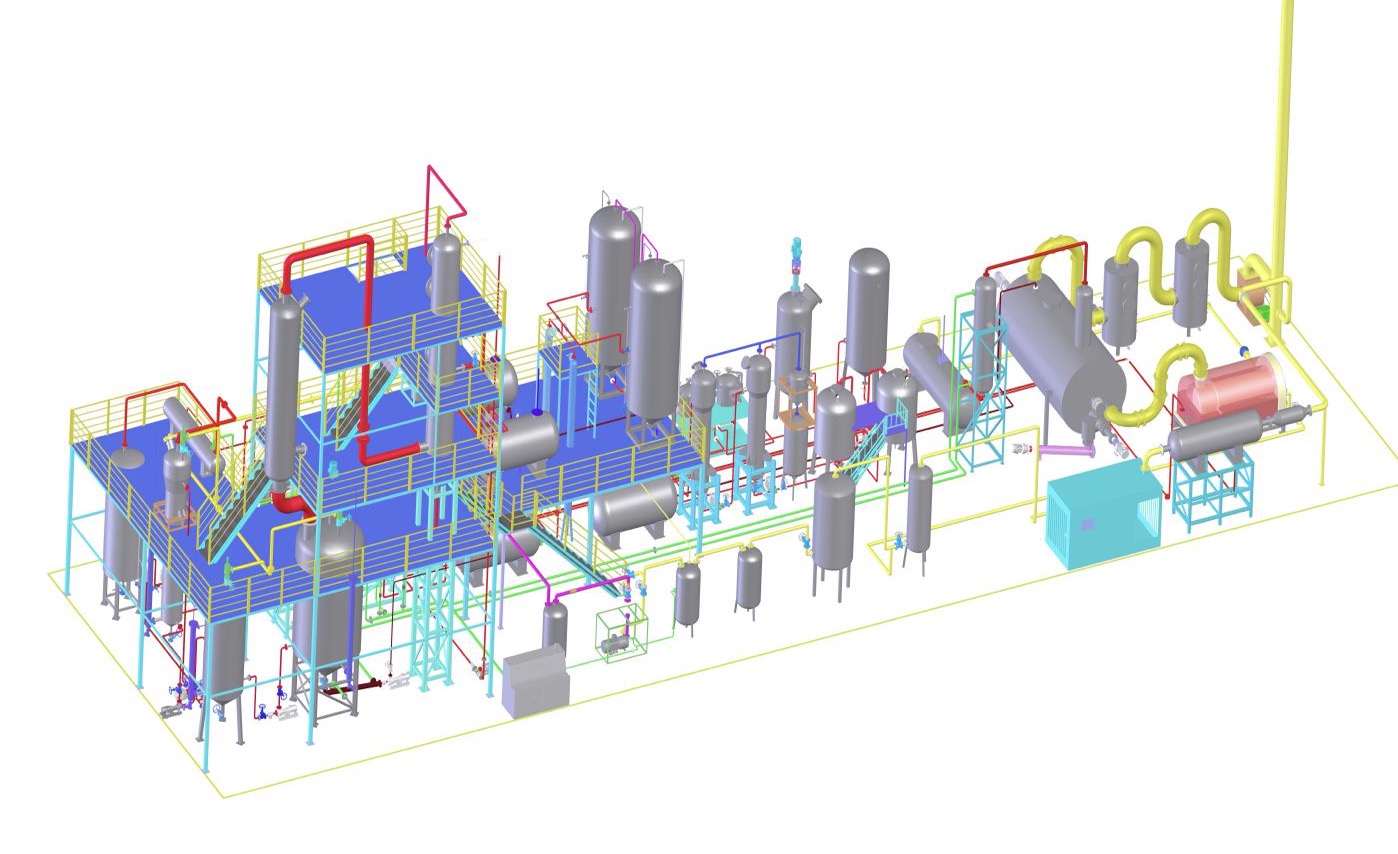

Company Profile:

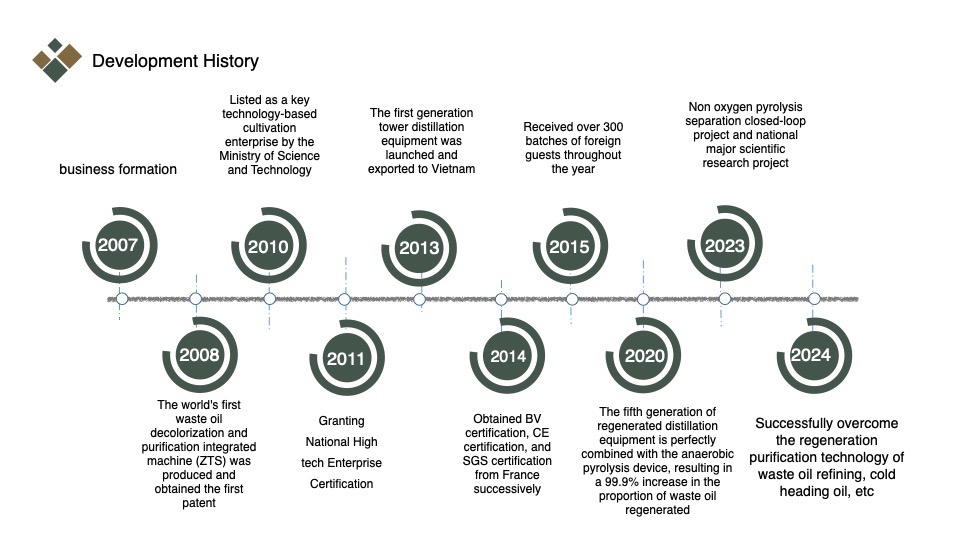

Chongqing Fangsheng Purification Equipment Co., Ltd. has been committed to the research and innovation of regeneration and recycling technologies for industrial waste oil and chemical solvents since its establishment in 2007. The recycling rate of products processed by our company's equipment can reach over 99%, with almost zero emissions, providing a good solution for enterprises to reduce costs and increase efficiency, and effectively promoting the development of environmental protection and resource recycling.

FAQ:

Q: Will the anti-wear factor in the lubricant be damaged or lost after being decolorized and filtered by the equipment?

A: As DTS6 operates at medium to low temperatures, it can completely restore its appearance and kinematic viscosity without damaging its anti-wear factor.

Q: What is the replacement cycle for the filter element of DTS-6

A: DTS-6 adopts the latest technology. No need to replace the filter element, just clean it regularly.

Q: What is the oil yield of DTS-6?

A: 90% -99%. The specific oil yield should be determined based on the raw materials.

Q: What is the degree of reduction of waste oil that can be achieved?

A: Due to our globally leading products, we are able to reduce oil products to 99.9% using the latest technology.

Q:What types of oil can DTS handle

A: DTS can process used single type waste oil (including lubricating oil/gear oil/chain oil/hydraulic oil, etc.)

Q:Can DTS handle waste oil mixed with multiple varieties

A:Can handle waste oil other than high-temperature engine oil

contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp at+85292340729.