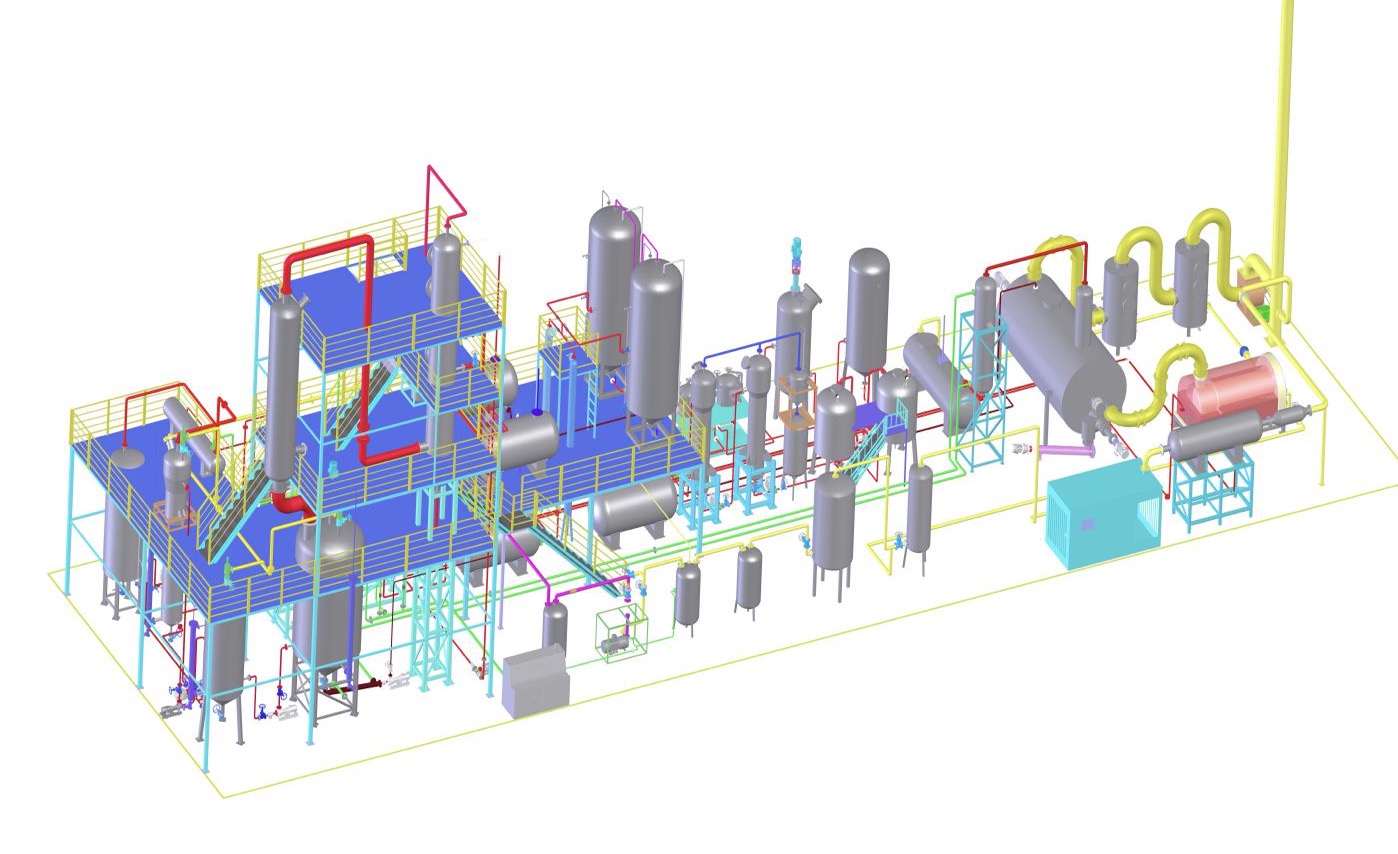

DTS-6 multifunctional decolorization and purification all-in-one machine It can purify waste oil at temperatures below 100 degrees without damaging the oil film, ensuring the highest oil quality and restoring the crude oil index to 99.9%.

|

Competing Industry Equipment |

Our Company's Equipment |

Comparative Advantages |

|

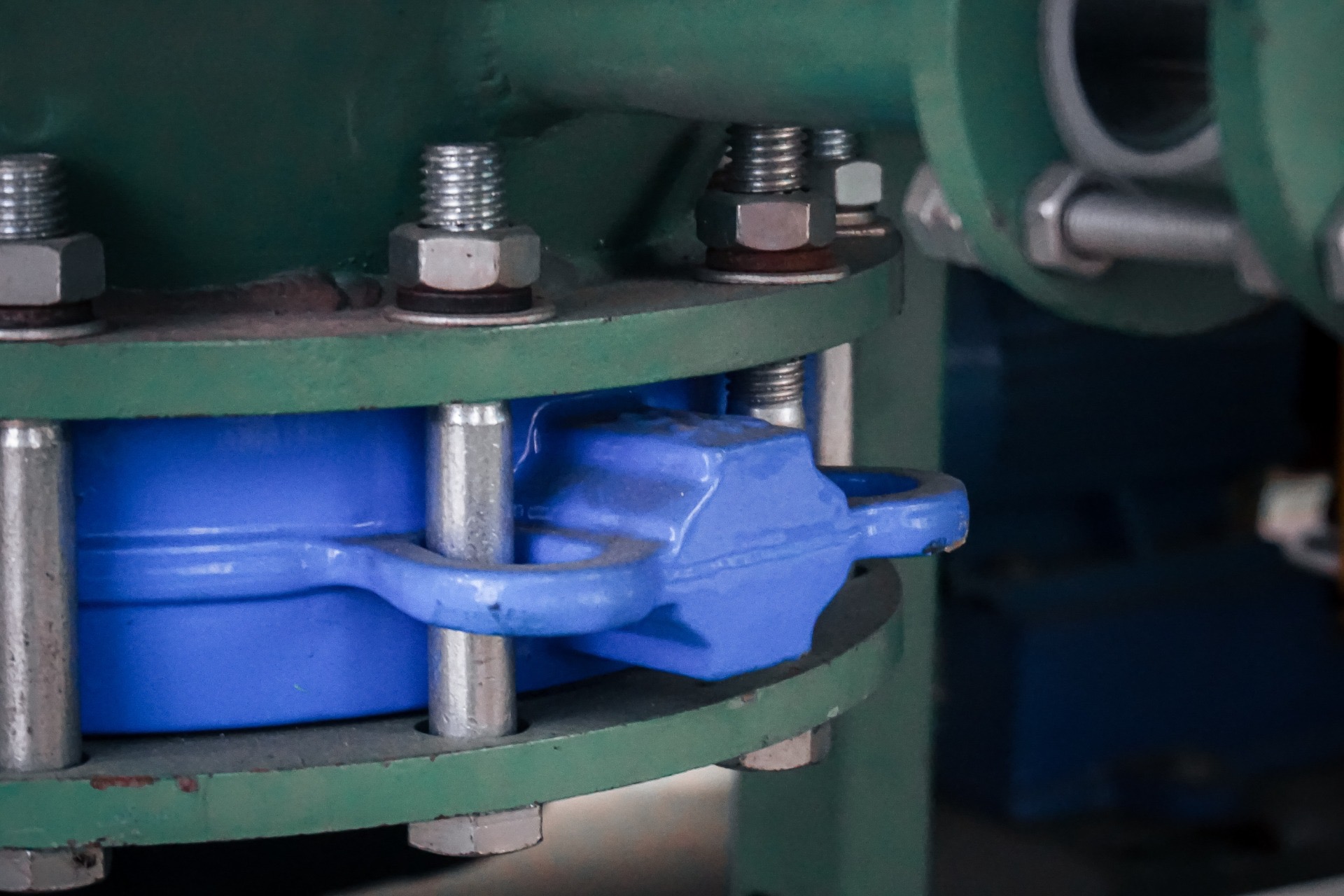

Filter elements or paper filters |

No filter elements |

Reduces consumable costs, eliminates the need for filter cleaning, easy to operate, saves time |

|

High electricity consumption |

Energy-efficient |

Uses electromagnetic induction, saving 50% on electricity |

|

Direct heating |

Constant temperature indirect heating |

Constant temperature heating protects the oil quality, preventing rapid aging of the oil |

|

High-temperature direct heating |

360-degree indirect surround heating |

Significantly improves safety |

|

Physical filtration |

Flocculation purification |

Can purify nanoscale impurities |

|

Direct evaporation to remove moisture |

Flocculation adsorption of moisture |

Saves energy, maintains the essence of the oil, does not produce sludge |

|

Cannot process heavily soiled oil |

No restrictions |

Broad processing range, strong processing capability |

|

Processed oil color is similar to waste oil |

Processed oil color is 99.9% similar to new oil |

Processed oil does not change color |

|

Can only accept moisture and mechanical impurities |

Meets national standards (GB)Can accept all indicators |

Allows customers to send samples for laboratory testing of all indicators |

|

Processed oil can only be used in simple cooling systems |

Reusable in the original system and equipment |

Can be used repeatedly in cycles |

|

Degradation of oil quality |

No degradation of oil quality |

Q: Will the anti-wear factor in the lubricant be damaged or lost after being decolorized and filtered by the equipment?

A: As DTS6 operates at medium to low temperatures, it can completely restore its appearance and kinematic viscosity without damaging its anti-wear factor。

Q: What is the replacement cycle for the filter element of DTS-6

A: DTS-6 adopts the latest technology. No need to replace the filter element, just clean it regularly.

Q: What is the oil yield of DTS-6?

A: 90% -99%. The specific oil yield should be determined based on the raw materials.

Q: What is the degree of reduction of waste oil that can be achieved?

A: Due to our globally leading products, we are able to reduce oil products to 99.9% using the latest technology.