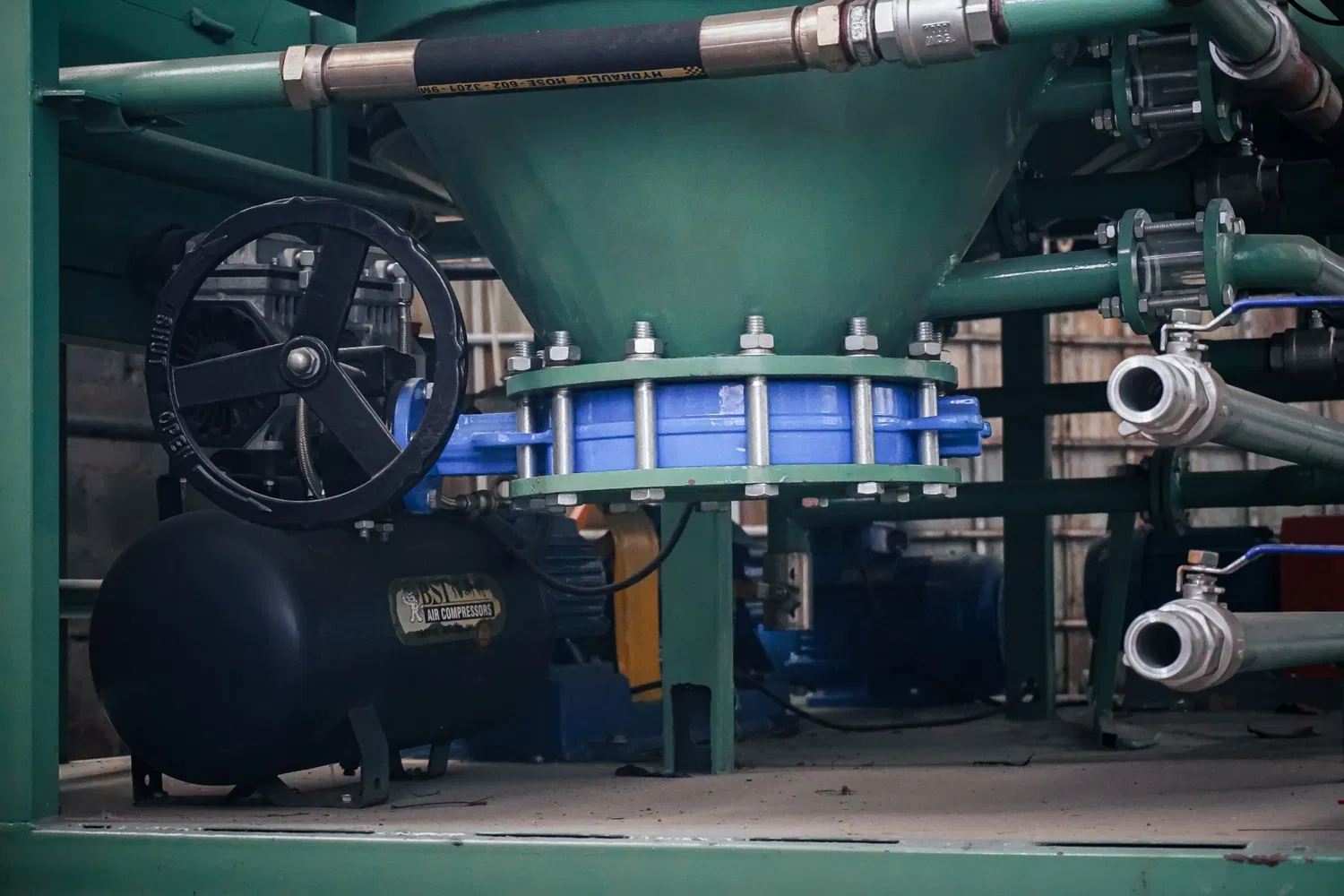

Oil purifier Industrial waste oil recycling machine No filter element Used Oil Refinery

Product Introduction:

|

|

|

DTS multifunctional decolorization and purification all-in-one machine product features:

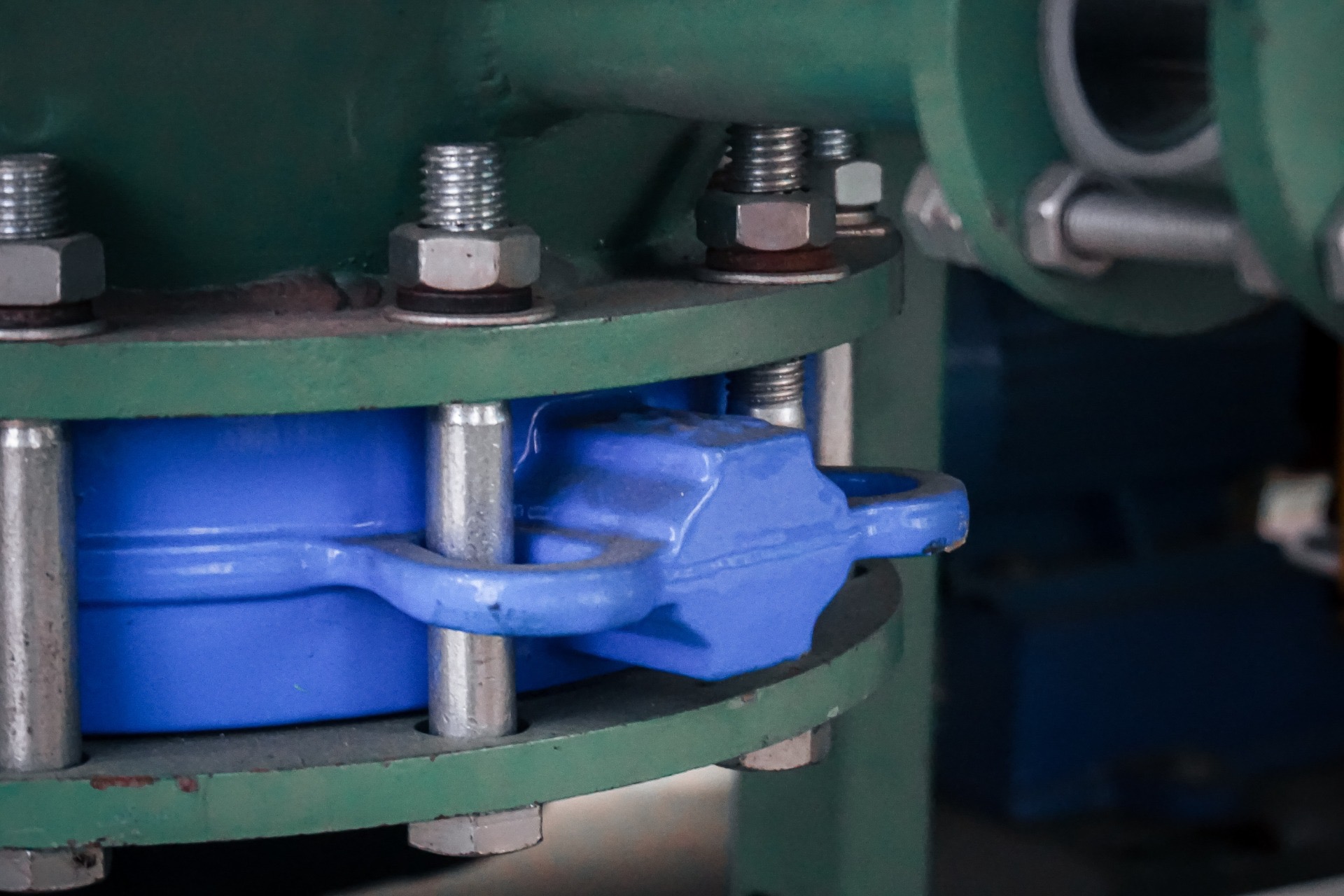

1: Filter free design: DTS adopts magnetic field filtration technology, which eliminates the need for filter cartridges, screens or filter paper, avoiding the high cost and tedious operation caused by frequent replacement of consumables in traditional oil purifiers, while reducing downtime and improving operational efficiency.

2: Efficient purification: DTS' low-temperature (not exceeding 100 degrees) microfiltration technology can effectively remove impurities and moisture from oil products. The quality of processed oil products is higher. It can restore key indicators such as viscosity and flash point.

3: Energy saving and environmental protection: The average power of DTS is only one-third of that of traditional oil purifiers, greatly reducing energy consumption, eliminating the need to replace consumables, reducing waste generation, and making it more environmentally friendly.

4: Automation and Convenience: DTS is equipped with automatic feeding, slag removal, and backwashing functions, which are easy to operate, while traditional oil purifiers are complex to operate and require frequent manual replacement of filter paper and cleaning of filter residue.

5: Customized services: DTS can customize different specifications and production volumes according to customer needs, flexibly adapting to various industrial scenarios. Traditional oil purifiers have fixed specifications and are difficult to meet diverse needs.

Oil purifier Industrial waste oil recycling machine,Industrial waste oil recycling machine No filter element,No filter element Used Oil Refinery,Oil purifier Industrial waste oil recycling machine No filter element,Industrial waste oil recycling machine No filter element Used Oil Refinery,Oil purifier Industrial waste oil recycling machine No filter element Used Oil Refinery

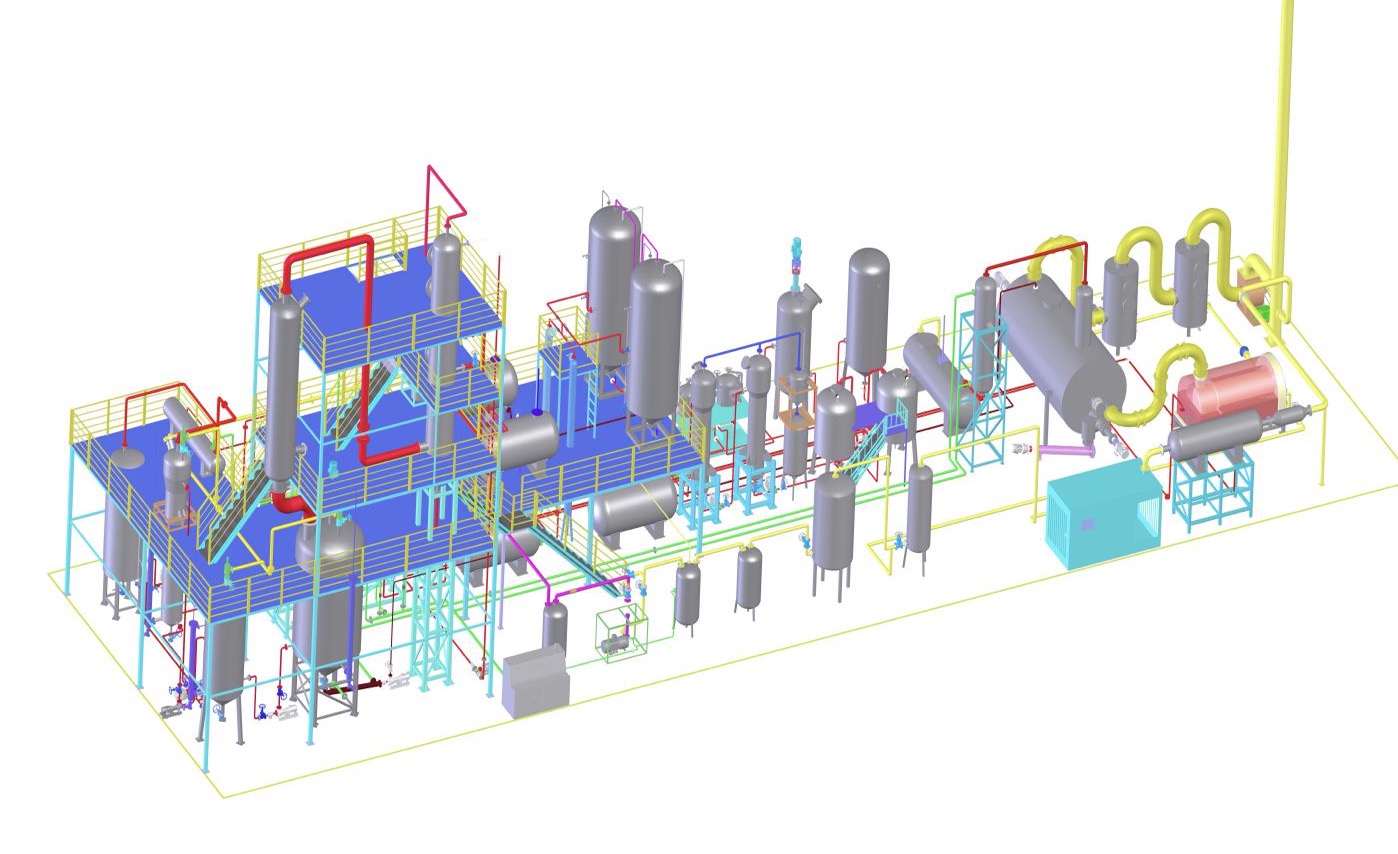

Comparison diagram of waste oil regeneration:

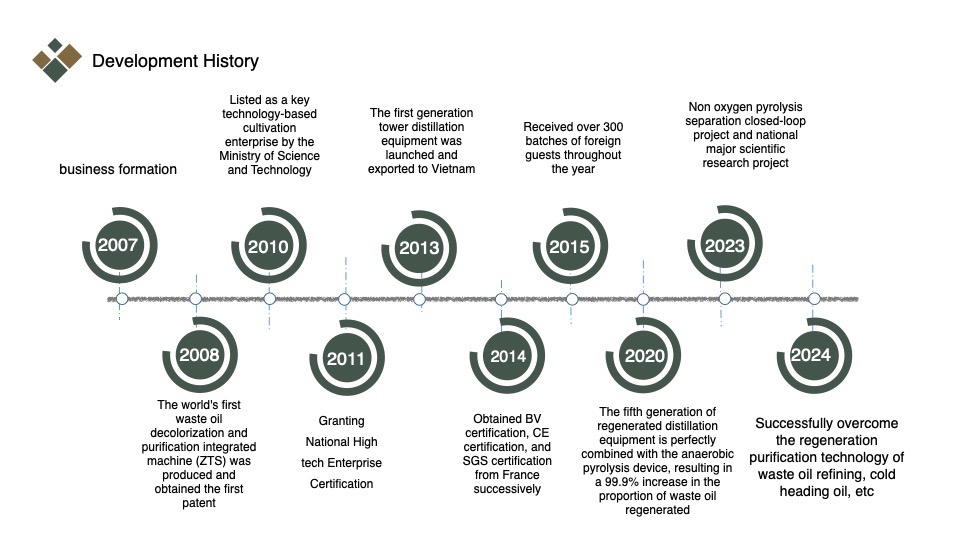

Company Profile:

Since its establishment in 2007, Chongqing Fangsheng Purification Equipment Co., Ltd. has been a pioneer in the field of industrial waste oil treatment and chemical solvent recycling. Our company leads the industry with advanced technologies in purification equipment, including unique filter-free systems, energy-efficient operations, and advanced separation techniques. With over 100 patents, our equipment achieves a recycling rate of over 99% with near-zero emissions. This not only provides enterprises with an efficient solution for cost reduction and efficiency enhancement but also makes significant contributions to environmental protection and sustainable resource recycling.

Oil purifier Industrial waste oil recycling machine,Industrial waste oil recycling machine No filter element,No filter element Used Oil Refinery,Oil purifier Industrial waste oil recycling machine No filter element,Industrial waste oil recycling machine No filter element Used Oil Refinery,Oil purifier Industrial waste oil recycling machine No filter element Used Oil Refinery

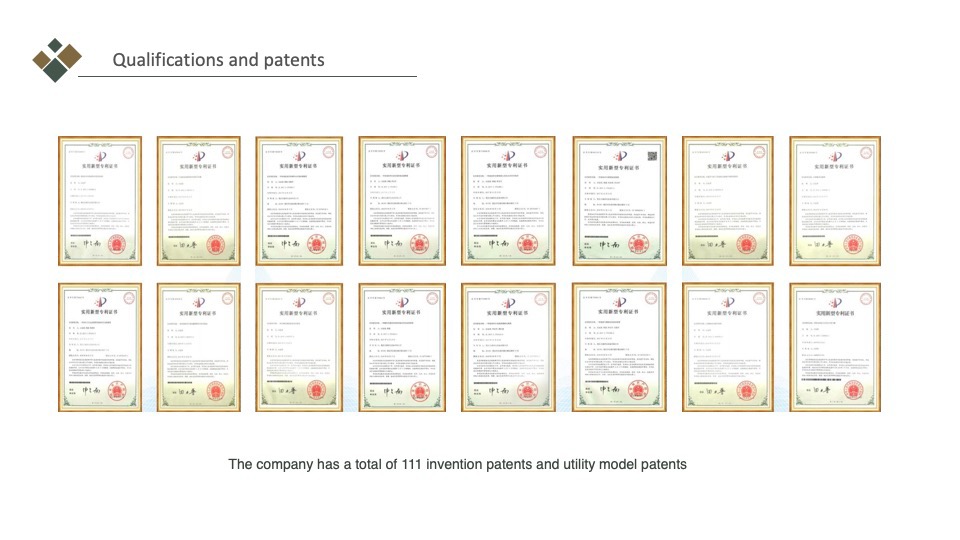

Patent Introduction:

Since its establishment, Chongqing Fangsheng Purification Equipment Co., Ltd. has been deeply committed to technological innovation and R&D in the field of industrial waste oil treatment and chemical solvent recycling. Over the years, the company has successively obtained more than 100 patents, covering a wide range of core technologies such as filtration-free systems, advanced separation techniques, and energy-efficient processes. These patents not only reflect the company's continuous efforts in R&D but also highlight its leading position in the industry.

FQA:

Q: Will the anti-wear factor in the lubricant be damaged or lost after being decolorized and filtered by the equipment?

A: As DTS6 operates at medium to low temperatures, it can completely restore its appearance and kinematic viscosity without damaging its anti-wear factor.

Q: What is the replacement cycle for the filter element of DTS-6

A: DTS-6 adopts the latest technology. No need to replace the filter element, just clean it regularly.

Q: What is the oil yield of DTS-6?

A: 90% -99%. The specific oil yield should be determined based on the raw materials.

Q: What is the degree of reduction of waste oil that can be achieved?

A: Due to our globally leading products, we are able to reduce oil products to 99.9% using the latest technology.

Q:What types of oil can DTS handle

A: DTS can process used single type waste oil (including lubricating oil/gear oil/chain oil/hydraulic oil, etc.)

Q:Can DTS handle waste oil mixed with multiple varieties

A:Can handle waste oil other than high-temperature engine oil

Contact Us:

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp at:+85292340729.