Oil purifier Waste engine oil filtration machinery Oil output of over 95% Used Oil Refinery

Product Introduction:

|

|

|

1: Low temperature purification: The machine operates at temperatures below 100 degrees Celsius to ensure that the oil film is not damaged and maintain the highest oil quality.

2: Effective recycling of waste oil: Various types of waste oil can be recycled, including lubricating oil, anti-wear hydraulic oil, engine oil, gear oil, and chain oil. The purified oil meets the standards of new oil and can be reused in existing equipment without causing damage.

3: Innovative flocculation technology: This machine adopts the latest flocculation technology and does not require the use of filter elements. This technology can purify nanoscale impurities and ensure that the processed oil has 99.9% similarity to the new oil.

4: No filter element: No filter element can reduce the cost of consumables, without the need for frequent replacement or cleaning.

5: Energy efficiency: This machine uses electromagnetic heating, which can save up to 50% of electricity compared to traditional methods.

6: Wide processing range: capable of handling heavy oil stains, all indicators meet national standards.

7: Environmental and economic benefits: By reducing the demand for consumables and lowering energy consumption, machines become more environmentally friendly and cost-effective. It also enhances the market competitiveness of enterprises by reducing production costs.

Oil purifier Waste engine oil filtration machinery,Waste engine oil filtration machinery Oil output of over 95%,Oil output of over 95% Used Oil Refinery,Oil purifier Waste engine oil filtration machinery Oil output of over 95%,Waste engine oil filtration machinery Oil output of over 95% Used Oil Refinery,Oil purifier Waste engine oil filtration machinery Oil output of over 95% Used Oil Refinery

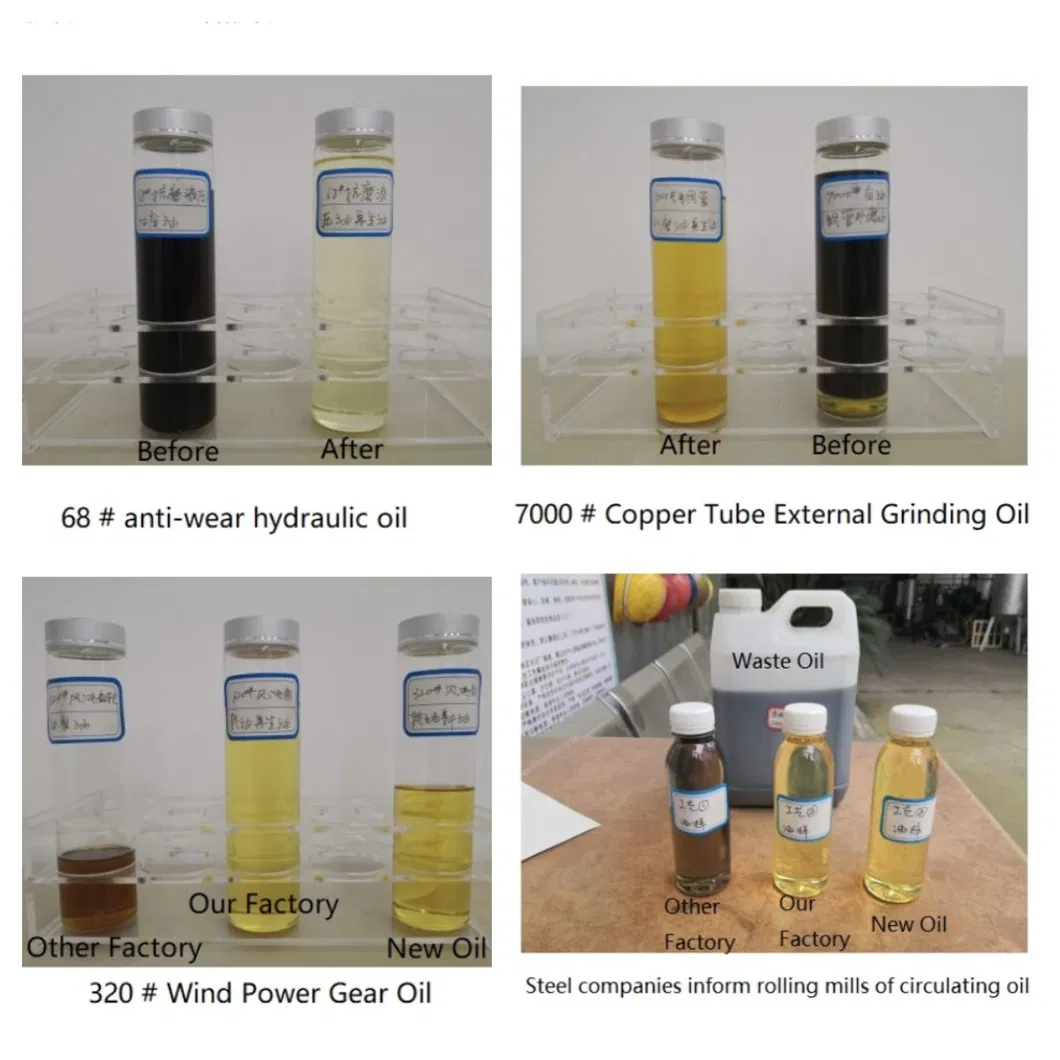

Comparison diagram of waste oil regeneration

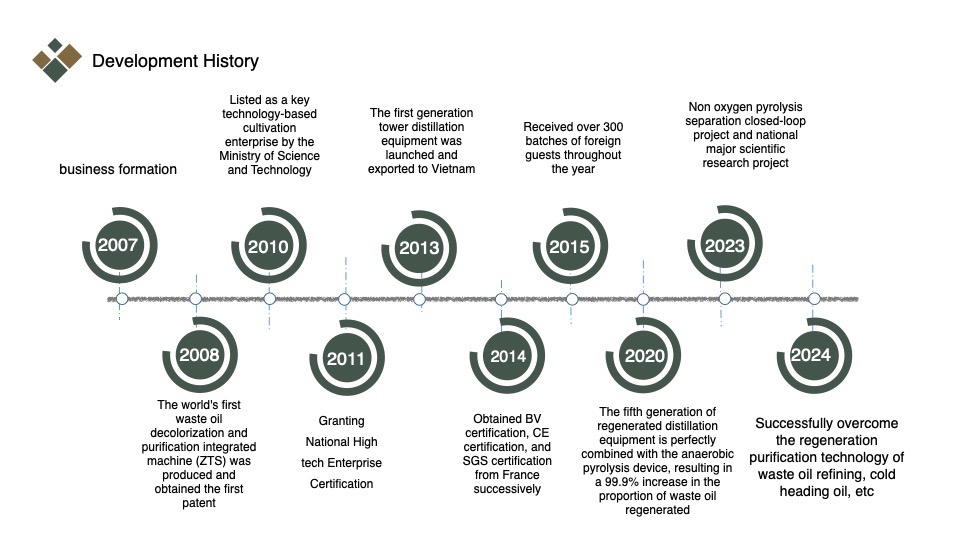

Company Profile

Oil purifier Waste engine oil filtration machinery,Waste engine oil filtration machinery Oil output of over 95%,Oil output of over 95% Used Oil Refinery,Oil purifier Waste engine oil filtration machinery Oil output of over 95%,Waste engine oil filtration machinery Oil output of over 95% Used Oil Refinery,Oil purifier Waste engine oil filtration machinery Oil output of over 95% Used Oil Refinery

Patent Introduction

Partner photo

FAQ

Q: Will the anti-wear factor in the lubricant be damaged or lost after being decolorized and filtered by the equipment?

A: As DTS6 operates at medium to low temperatures, it can completely restore its appearance and kinematic viscosity without damaging its anti-wear factor.

Q: What is the replacement cycle for the filter element of DTS-6

A: DTS-6 adopts the latest technology. No need to replace the filter element, just clean it regularly.

Q: What is the oil yield of DTS-6?

A: 90% -99%. The specific oil yield should be determined based on the raw materials.

Q: What is the degree of reduction of waste oil that can be achieved?

A: Due to our globally leading products, we are able to reduce oil products to 99.9% using the latest technology.

Q:What types of oil can DTS handle

A: DTS can process used single type waste oil (including lubricating oil/gear oil/chain oil/hydraulic oil, etc.)

Q:Can DTS handle waste oil mixed with multiple varieties

A:Can handle waste oil other than high-temperature engine oil

Contact Us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp at:+85292340729.