Waste liquid pressure oil treatment equipment oil filtration Latest technology for waste oil treatment

Product Introduction

Key Features:

-

High Distillation Efficiency and Yield

The FS-HDM5 achieves oil recovery rates of over 98%, significantly higher than traditional distillation equipment. -

Energy-Saving and Environmental Protection

The equipment uses electromagnetic induction heating technology, which is more energy-efficient and safer than traditional heating methods. It operates with near-zero emissions, meeting stringent environmental requirements. -

Low Maintenance Costs

The main reaction material can withstand temperatures up to 1500°C, effectively preventing carbon buildup and blockages, which significantly reduces maintenance costs. -

Customized Solutions

The FS-HDM5 can be tailored to meet specific customer needs, including processing capacity and operational requirements, to suit different industries and application scenarios. -

Advanced Technology

The equipment integrates multiple innovative technologies, such as anaerobic pyrolysis separation systems and efficient catalysts, ensuring high-quality oil regeneration while minimizing the generation of hazardous waste. -

Wide Application

The FS-HDM5 is widely used in industries such as petroleum, chemical, mechanical manufacturing, shipping, and power, and is particularly effective in the treatment of waste oils for hazardous waste categories HW08 and HW09.

Comparison diagram of waste oil regeneration

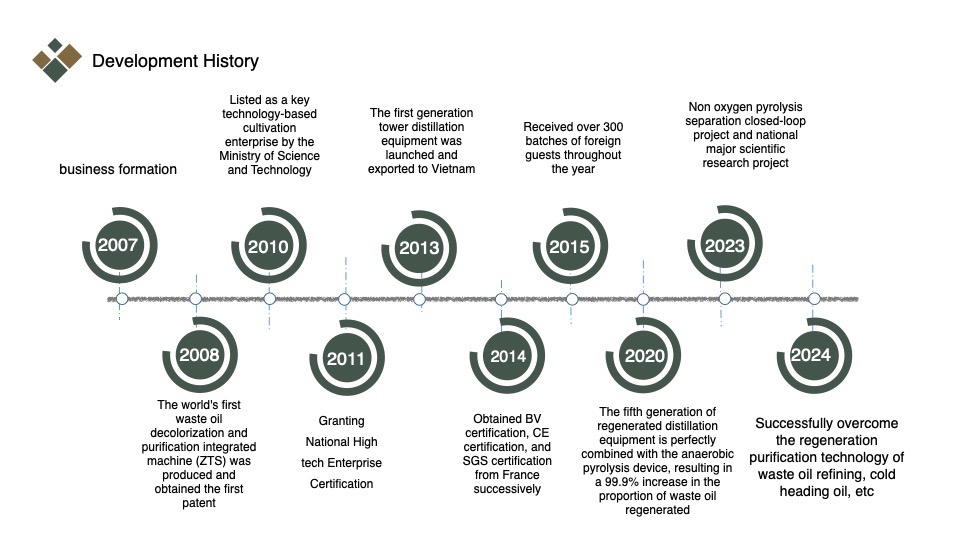

Company Introduction

Waste liquid pressure oil treatment equipment oil filtration,oil filtration Latest technology for waste oil treatment,Waste liquid pressure oil treatment equipment oil filtration Latest technology for waste oil treatment

Patent Introduction

Customer photo

FAQ

Q:What is the oil yield of this equipment for refining waste oil?

A:The oil yield of the equipment is greatly related to the original feedstock. However, our equipment can achieve an oil yield 20% higher than similar products.

Q:Is the operation of this equipment complicated? Does it require frequent maintenance?

A:The operation of this equipment is simple and convenient, and unlike traditional equipment, it does not require regular shutdowns for maintenance. With proper operation, a check can be done every few months.

Q:Can your company provide a feasibility analysis report for the waste oil refining project?

A:If your company can provide the source of the oil and the processing volume, as well as the required standards for treatment, we can provide a feasibility analysis report for this project for free.

Q:Does the operation of this equipment have additional hazardous waste emissions?

A:No, our leading technology can achieve almost zero emissions.

Q: What kind of waste oil can this equipment process?

A: This equipment can handle any condition of industrial waste oil or oil sludge, including lubricating oil, gear oil, engine oil, hydraulic oil, and mixtures thereof.

Q:How long does it take for the complete set of equipment to be delivered and put into use?

A:3 months

contact us

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp :at+85292340729.