Conversion of waste chain oil into base oil Distillation equipment Must choose waste refinery

Product Introduction

![]()

1.Our independently developed flocculation technology effectively removes nanoscale impurities, resulting in a finished product color close to that of new oil.

2.Different from the traditional heating tube heating system, our independently developed electromagnetic eddy current heating consumes less energy and has a higher safety factor.

3.Our independently developed main reaction material breaks through the temperature limit of 425 degrees for conventional distillation equipment materials on the market, capable of withstanding high temperatures up to 1500 degrees, thus achieving complete vaporization of oils and significantly increasing the oil yield.

4.Our independently developed main reaction tank is designed to never clog, greatly reducing maintenance costs and improving work efficiency and safety.

5.Our independently developed catalyst is more affordable, faster, and more thorough in chain breaking. It can be regenerated repeatedly, reducing costs and eliminating the generation of hazardous waste.

6.Used lubricating oil, gear oil, engine oil, chain oil, and other mixed industrial oils can be processed into fuel oil or base oil

Conversion of waste chain oil into base oil Distillation equipment,Distillation equipment Must choose waste refinery,Conversion of waste chain oil into base oil Distillation equipment Must choose waste refinery

Comparison diagram of waste oil regeneration

On the left is the oil processed by our company's oil purifier。

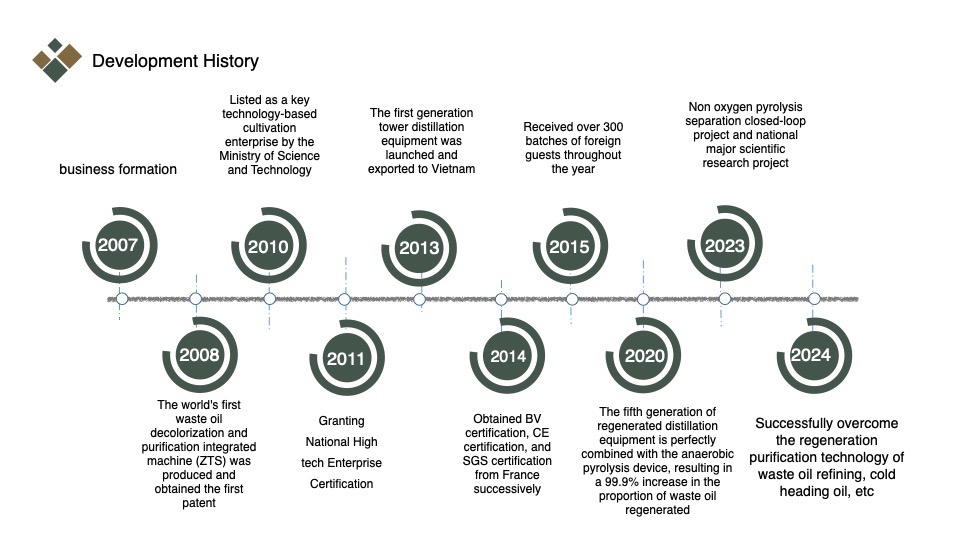

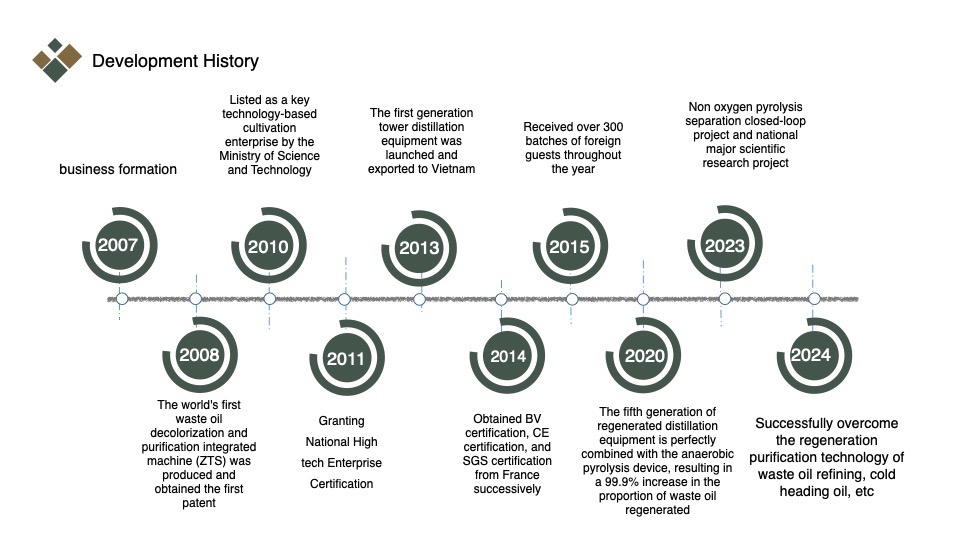

Company Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. is a leading high-tech enterprise specializing in the research and development of regeneration and purification technologies for industrial waste oil and waste liquids, as well as the manufacturing of related equipment. Innovation is at the core of the company's development. With over 100 patents covering key areas such as filter-free purification, efficient separation, low-temperature purification, and energy-saving processes, Fangsheng has established a strong technological advantage. The company's products are widely used in industries such as petroleum, chemical, mechanical manufacturing, shipping, and power, and are particularly effective in the treatment of hazardous waste. Flagship products include the DTS Multifunctional Low-Temperature Purification All-in-One Machine, the FS-HDM5 Complete Distillation Equipment, and the Anaerobic Carbonization Equipment. These products, known for their efficiency, environmental friendliness, and energy-saving features, have earned the trust of customers worldwide.

Conversion of waste chain oil into base oil Distillation equipment,Distillation equipment Must choose waste refinery,Conversion of waste chain oil into base oil Distillation equipment Must choose waste refinery

Patent Introduction

Chongqing Fangsheng Purification Equipment Co., Ltd. has obtained over 100 patents through continuous innovation in the field of industrial waste oil treatment and chemical solvent recycling. These patents cover key areas such as filter-free purification, efficient separation, low-temperature purification, and energy-saving technologies. They provide a solid technical foundation for the company's products, significantly enhance its market competitiveness, and establish a leading position in technology on a global scale.

Customer photo

Our company boasts a diverse clientele, with customers spanning both domestic and international markets.

Conversion of waste chain oil into base oil Distillation equipment,Distillation equipment Must choose waste refinery,Conversion of waste chain oil into base oil Distillation equipment Must choose waste refinery

FAQ

Q:What is the oil yield of this equipment for refining waste oil?

A:The oil yield of the equipment is greatly related to the original feedstock. However, our equipment can achieve an oil yield 20% higher than similar products.

Q:Is the operation of this equipment complicated? Does it require frequent maintenance?

A:The operation of this equipment is simple and convenient, and unlike traditional equipment, it does not require regular shutdowns for maintenance. With proper operation, a check can be done every few months.

Q:Can your company provide a feasibility analysis report for the waste oil refining project?

A:If your company can provide the source of the oil and the processing volume, as well as the required standards for treatment, we can provide a feasibility analysis report for this project for free.

Q:Does the operation of this equipment have additional hazardous waste emissions?

A:No, our leading technology can achieve almost zero emissions.

Q: What kind of waste oil can this equipment process?

A: This equipment can handle any condition of industrial waste oil or oil sludge, including lubricating oil, gear oil, engine oil, hydraulic oil, and mixtures thereof.

Q:How long does it take for the complete set of equipment to be delivered and put into use?

A:3 months

contact us

-

If you are interested in our product

You can do it through email: beyondfirstJRT@gmail.com

Or contact us on WhatsApp :at+85292340729.

-