Company Profile

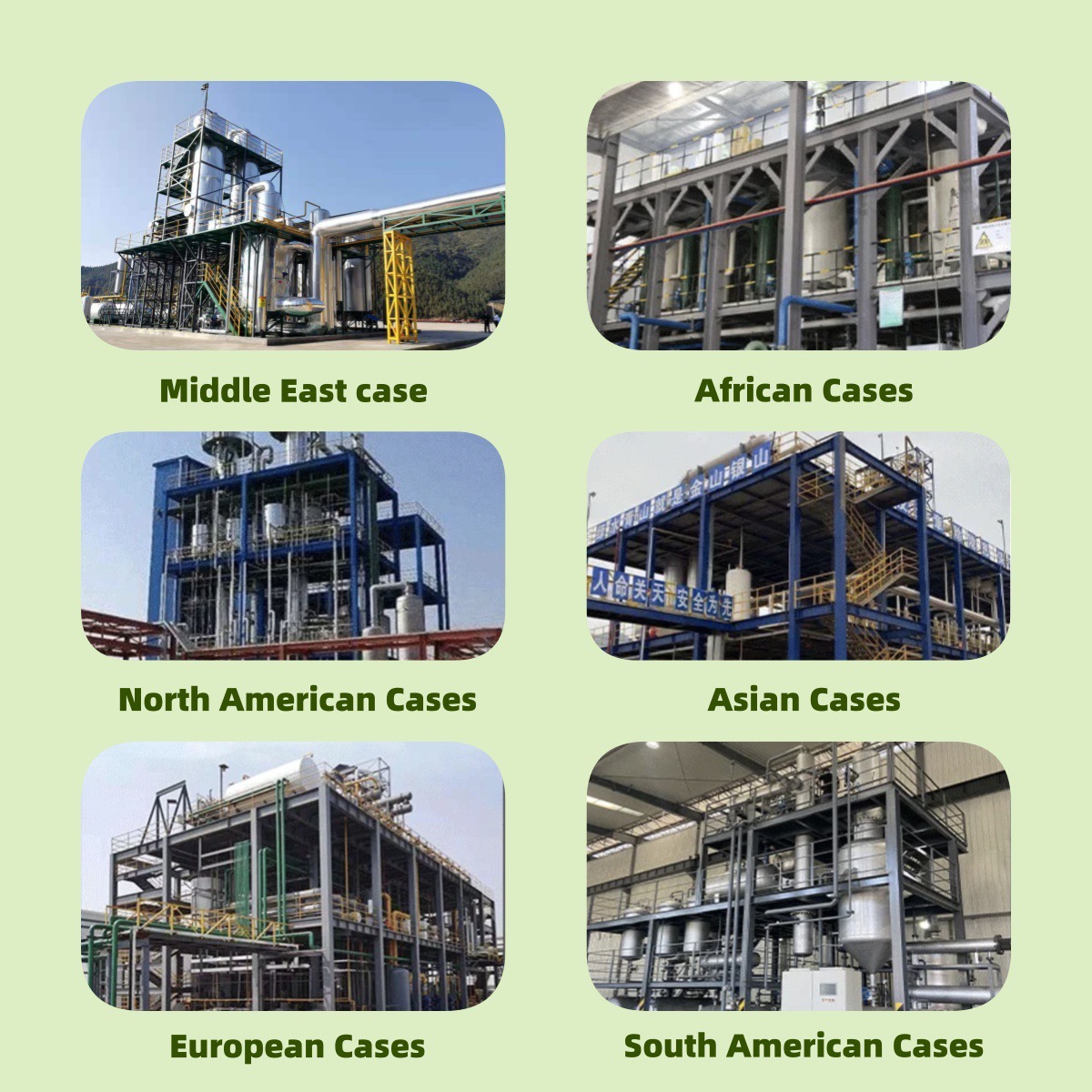

Chongqing Fangsheng Purification Equipment Co., Ltd. has been committed to the research and innovation of regeneration and recycling technologies for industrial waste oil and chemical solvents since its establishment in 2007. The recycling rate of products processed by our company's equipment can reach over 99%, with almost zero emissions, providing a good solution for enterprises to reduce costs and increase efficiency, and effectively promoting the development of environmental protection and resource recycling.

Industry background

Since its establishment, our company has been committed to the research of hazardous waste treatment in the petrochemical industry. From various waste engine oils, gear oils, hydraulic oils, sludge, waste tires, etc. in the petroleum industry, to solvent purification and regeneration, solution purification and treatment in the pharmaceutical and biochemical industries to meet emission standards. Over the past 14 years, we have served nearly a thousand businesses, helping them save costs, create value through regeneration, and greatly reduce environmental pollution.

Product advantages

30% more energy-efficient than similar devices

20% higher processing and recycling rate than similar devices

We can design the most suitable hazardous waste treatment plan for you based on your needs

Core technology

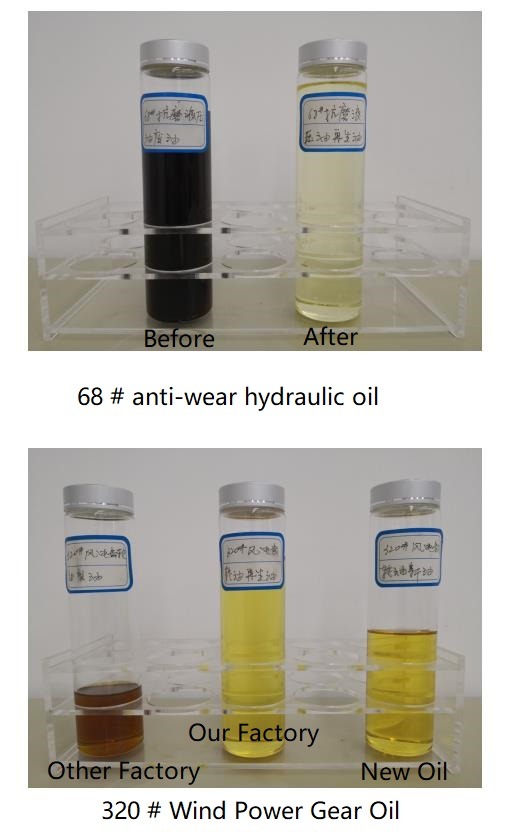

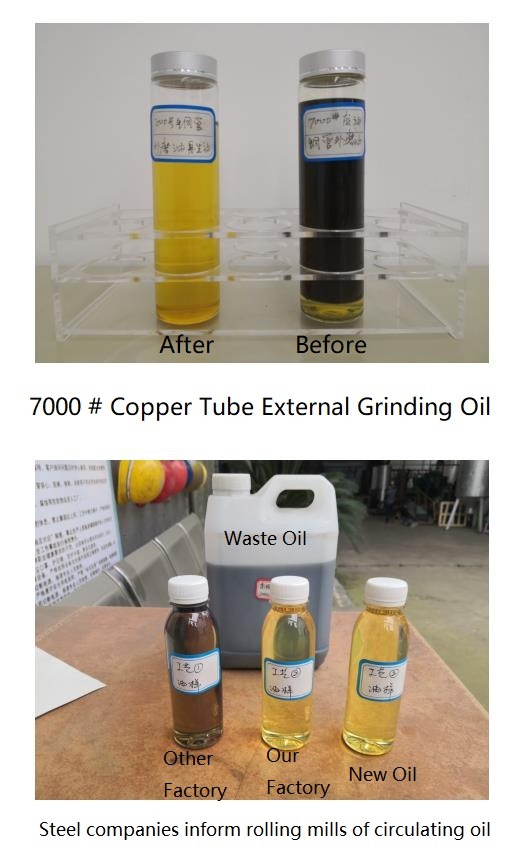

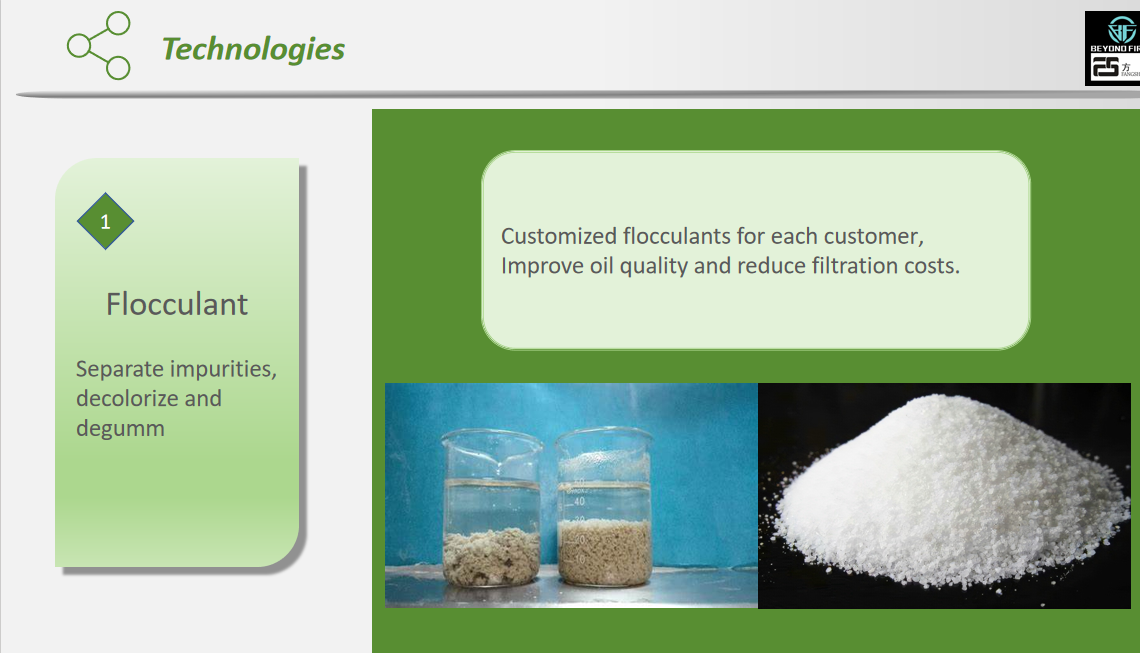

Our independently developed flocculation and flocculation technology removes most of the impurities in the oil and restores the color and quality of the oil

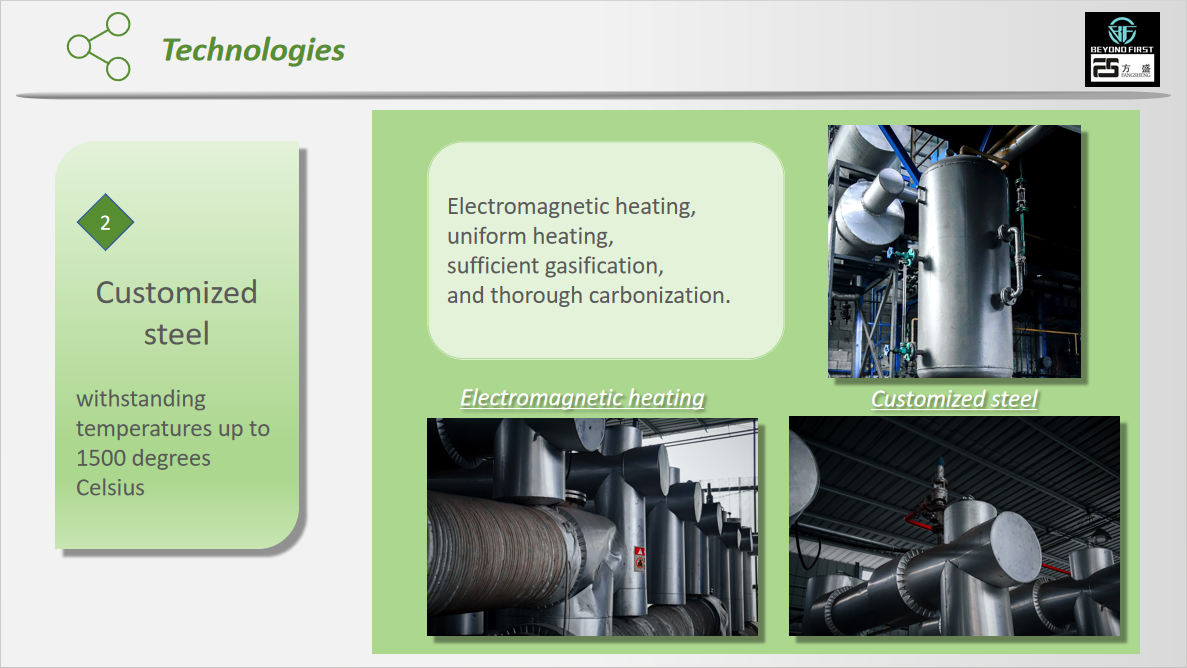

The independently developed main reaction material can withstand ultra-high temperatures of 1500 degrees Celsius, completely gasifying oil products and carbonizing solid parts

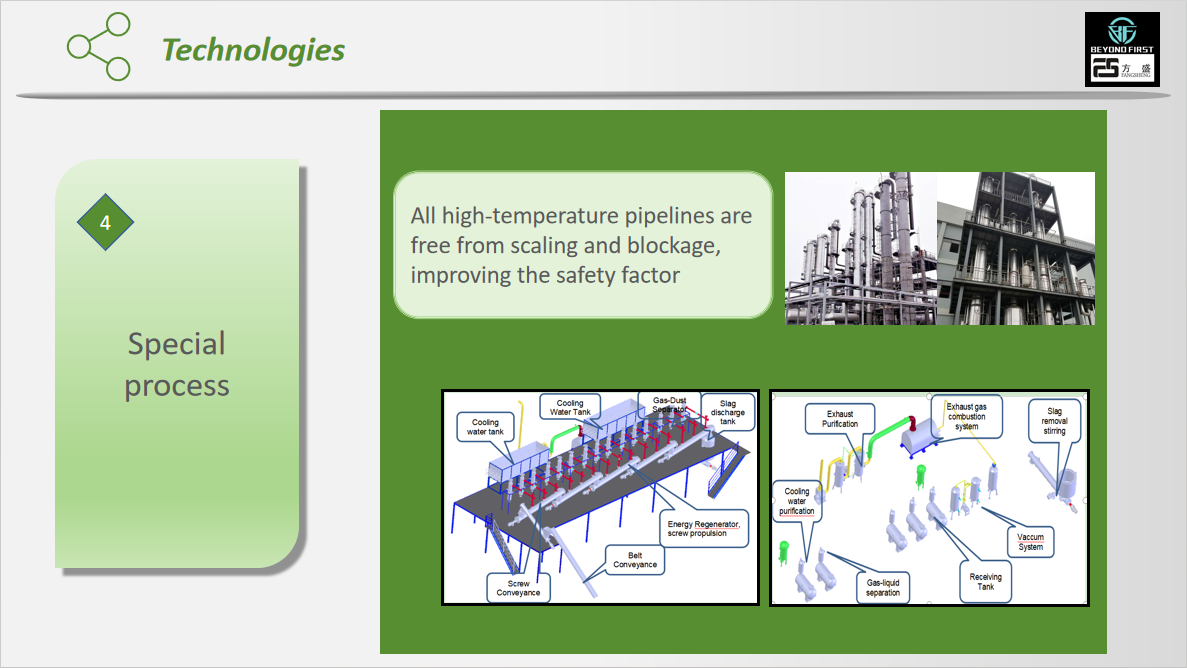

The independently developed internal structure never gets stuck, saving maintenance time and greatly improving efficiency

The independently developed catalyst has high efficiency and is renewable and recyclable

Patent certificate

Since 2007, we have independently developed over a hundred patented technologies

Purpose of products

1.Regeneration and recycling of waste oil from various mechanical equipment

2. Refining waste oil from petrochemicals into fuel oil to meet the demand standards of different countries.

3.Chemical solvent purification,and reach the emission standards

_68800.jpg)