Company Profile:

- Our company was established in 2007.

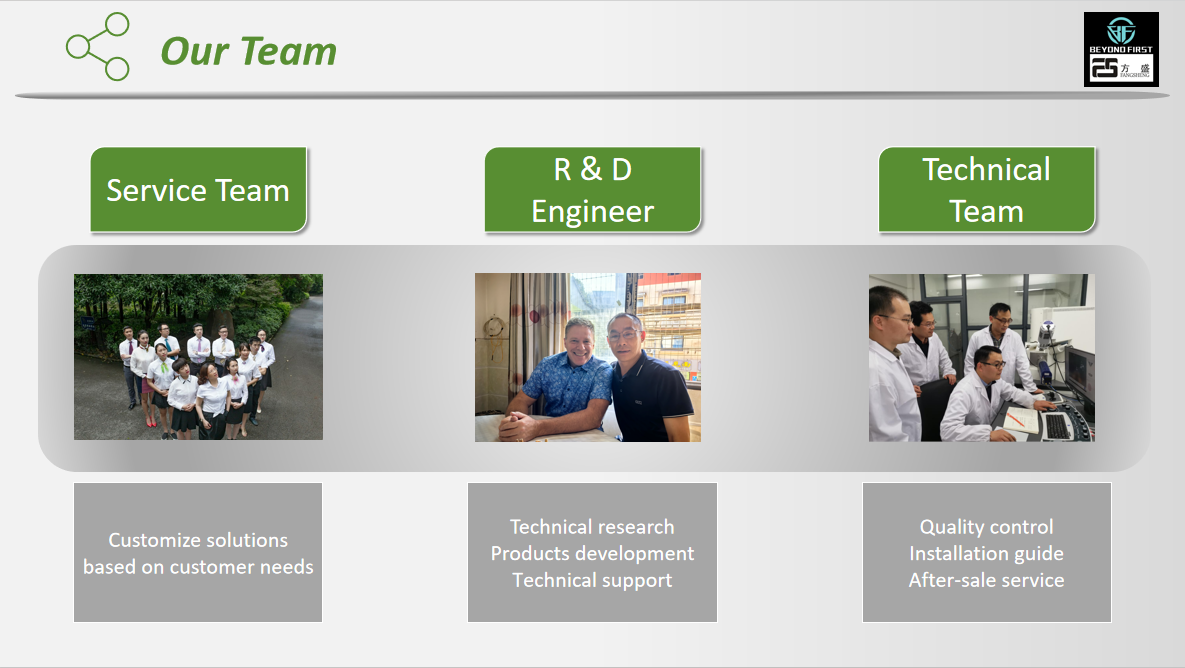

- It is an industrial and trade enterprise integrating R&D, manufacturing, sales, and services.

- The company's products are mainly aimed at the recycling and reuse of industrial waste oil, with a recycling rate of over 99%, achieving nearly zero emissions.

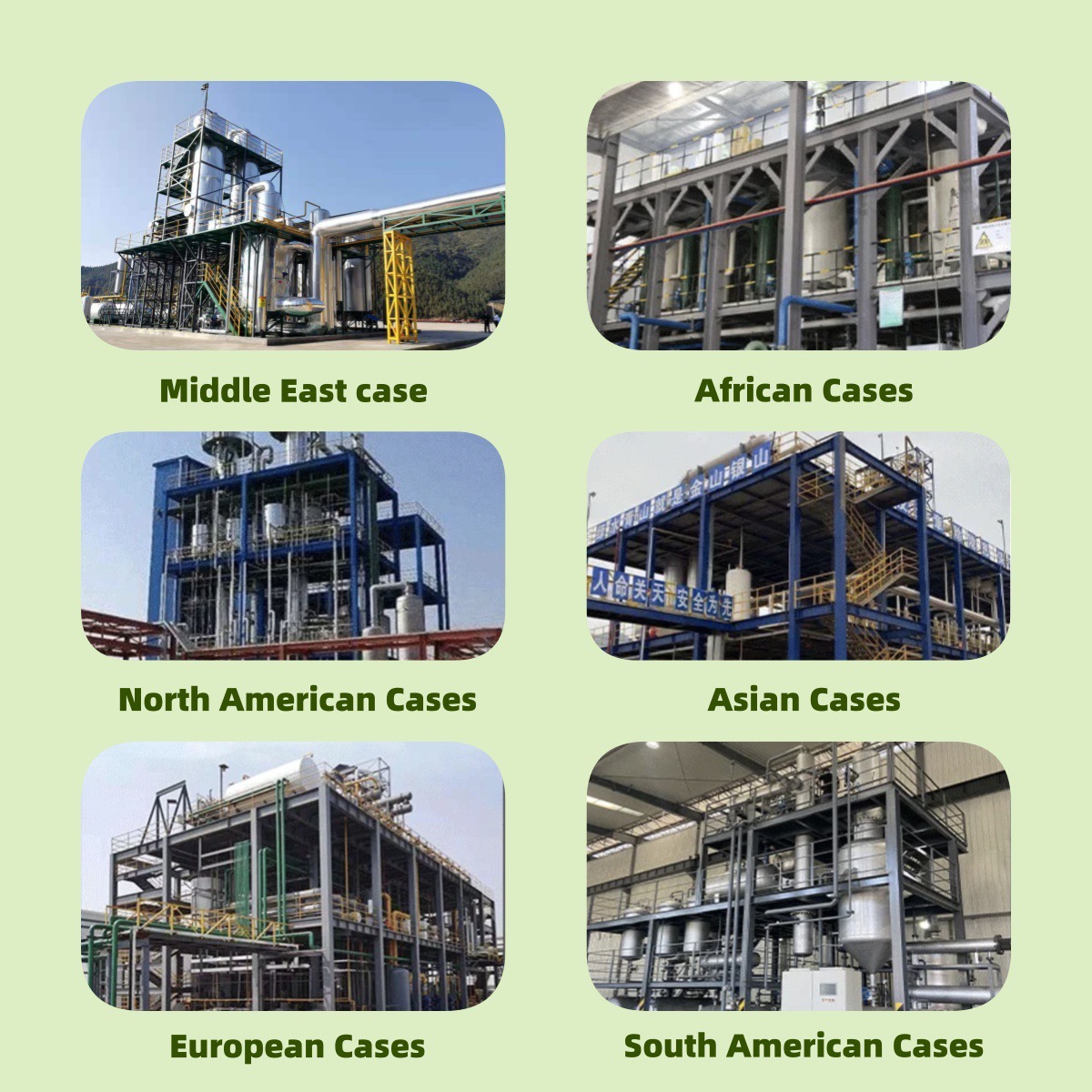

- The products cover nearly thirty provinces, autonomous regions, and municipalities directly under the Central Government in China.

- They are exported to countries and regions such as Europe, America, the Middle East, and the Asia-Pacific.

- The products are widely used in industries such as petroleum, chemical, papermaking, cement, metallurgy, machinery, bearings, mining, electric power, shipbuilding, military, automotive, rubber and plastics, instruments, transportation, building materials, etc., for the recycling and utilization of hazardous waste resources.

- The company has hundreds of innovative invention patents, is a national high-tech enterprise, holds dozens of scientific and technological achievements and copyrights, and leads the industry in product technology in the field of energy recycling and reuse.

- The company has a professional technical team that can customize product combinations according to the specific needs of customers.

Product Overview

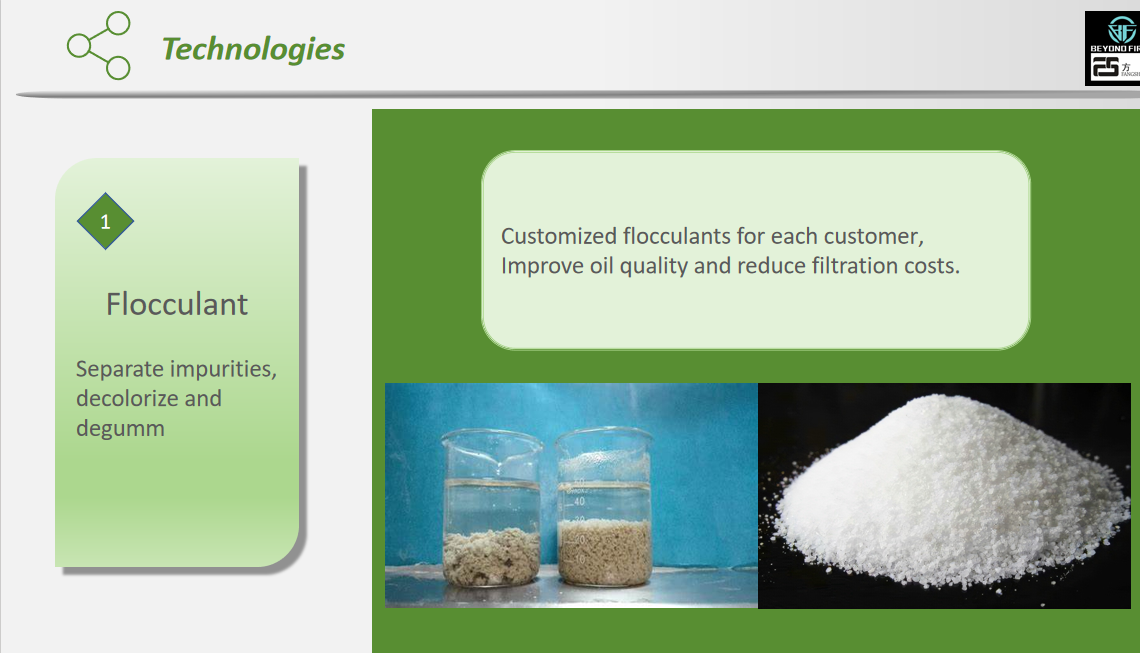

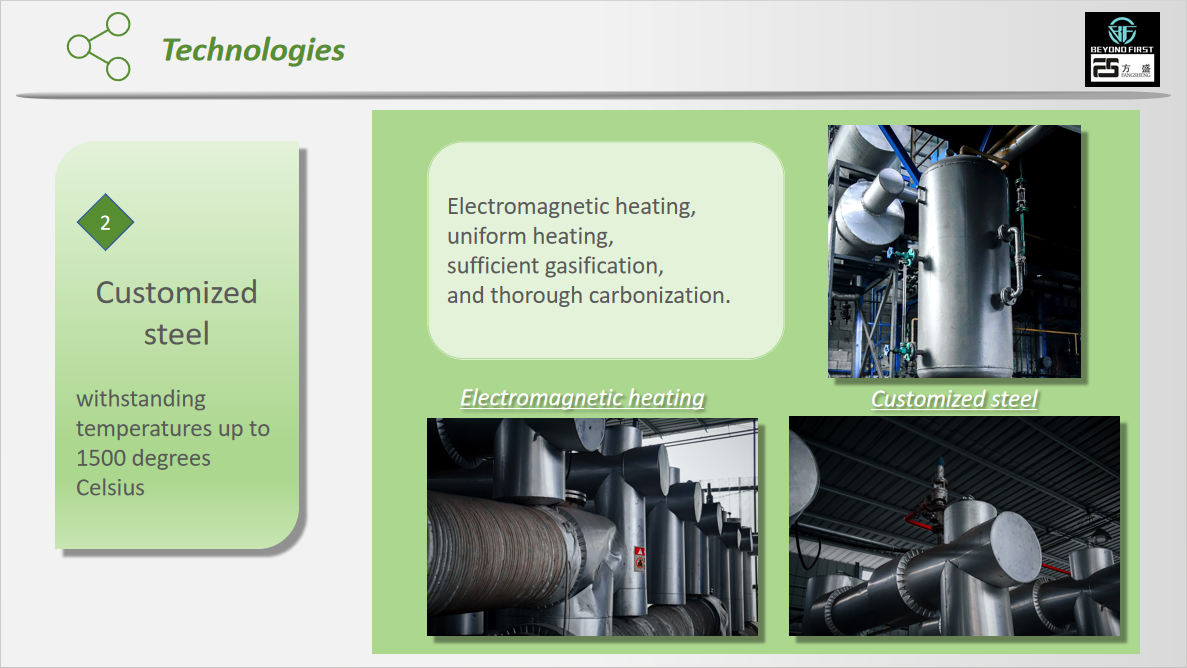

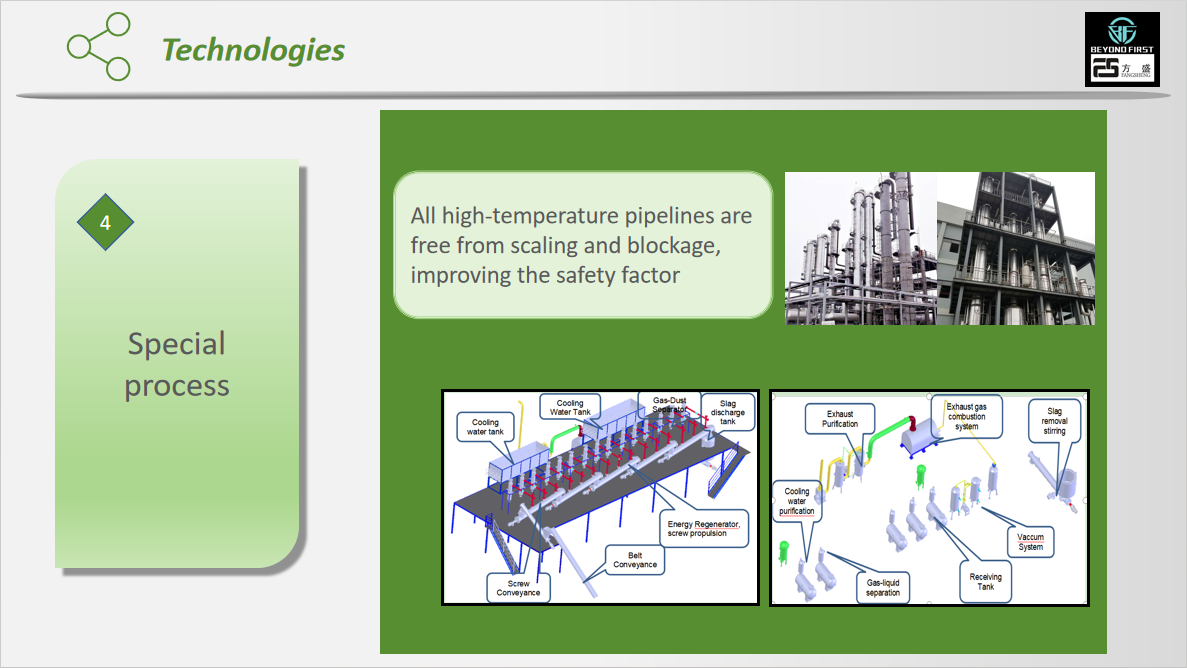

The special innovation full bridge rectification technology combines the multi-stage differentiation of traditional refining methods with traditional distillation, electromagnetic medium heating, polymer bubble decolorization, and falling film separation for distillation treatment of oil products. It is an environmentally friendly, energy-saving, efficient, and safe waste mineral oil refining device.

System of Regeneration Distillation Complete Set of Equipment

The process of this Equipment

Twice pretreatment system for waste oil

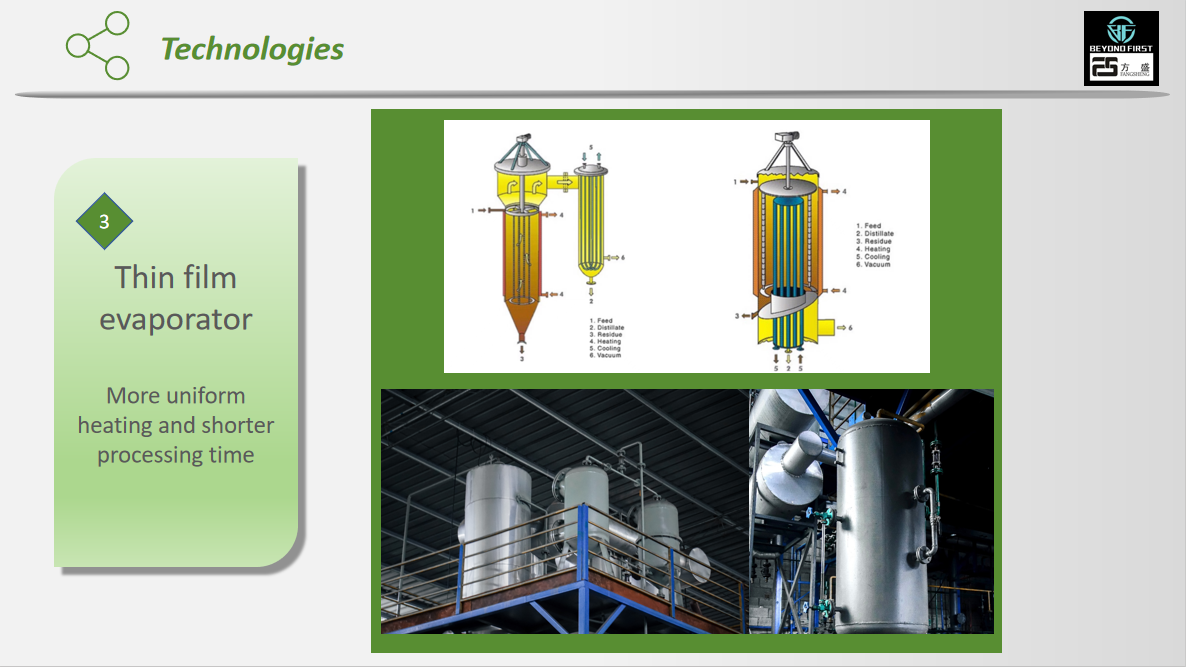

Thin film evaporation system

reaction system

Adsorption system

Multi stage process fractionation system

Cooling system

Heating system

Vacuum negative pressure pumping system

Exhaust gas treatment system

Integrated utilization system for waste heat recovery

Residue anaerobic solidification system

|

|

|

introduction

|

|

|

FAQ

Q:What is the oil yield of this equipment for refining waste oil?

A:The oil yield of the equipment is greatly related to the original feedstock. However, our equipment can achieve an oil yield 20% higher than similar products.

Q:Is the operation of this equipment complicated? Does it require frequent maintenance?

A:The operation of this equipment is simple and convenient, and unlike traditional equipment, it does not require regular shutdowns for maintenance. With proper operation, a check can be done every few months.

Q:Can your company provide a feasibility analysis report for the waste oil refining project?

A:If your company can provide the source of the oil and the processing volume, as well as the required standards for treatment, we can provide a feasibility analysis report for this project for free.

Q:Does the operation of this equipment have additional hazardous waste emissions?

A:No, our leading technology can achieve almost zero emissions.

Q:How long does it take for the complete set of equipment to be delivered and put into use?

A:3 months